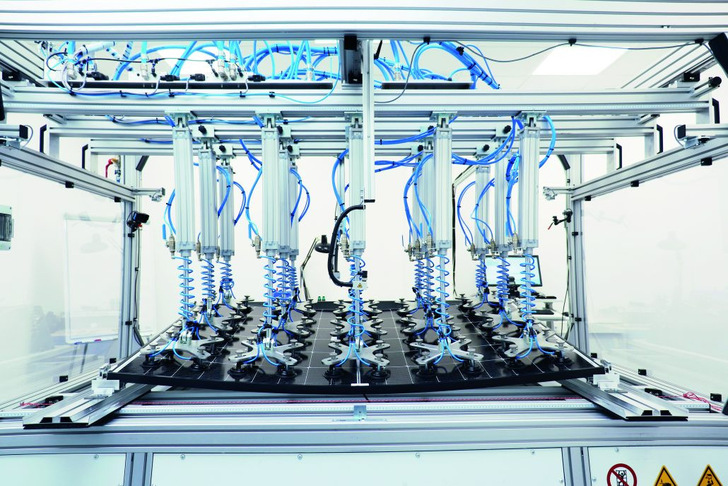

In order to guarantee the highest standards at all times, the IBC Solar PV modules and mounting systems are tested in the SunLab testing laboratory. The procedure involves a total of seven endurance tests for performance, stability and wear under various external conditions.

See also: Coburg University and IBC Solar develop solar tiny house

A key role is played by the load table, which performs a structure-mechanical load test of the entire solar module in combination with the mounting system. In accordance with the standard DIN EN IEC 61215-2:2022-02 (MQT16), the module is alternately pressed down and pulled up at 2,400 pascal of pressure. To simulate extra snow load, 5,400 pascal of pressure can even be applied. Height sensors are used to measure the deflection of the module and an electronic load is used to measure current and voltage To pass the test, the component in question must not exceed a given specifications.

Come see the process live at the IBC stand

In addition, the module must not be permanently bent or broken after the test and, according to the standard, must not lose more than 5 per cent of its capacity. IBC Solar even goes one step further and only accepts modules that have no more than 3 per cent of power loss after the tests.

Also interesting: IBC launches citizen participation platform for solar parks

The test process on the load table can be observed live at the IBC Solar trade fair stand. The live tests take place three times per day at the trade fair day at 11:00 a.m., 2:00 p.m. and 4:00 p.m. and the products have to prove their quality.

To see the test for yourself, see IBC Solar here: hall A4, stands 470 and 570. (mfo)