The compact serial solution is thus not only the first battery system to be manufactured at the Company's new site: By launching production of the AKARack for a globally operating manufacturer of construction machinery, AKASol ushers in a new era for quick and easy electrification of efficient and environmentally friendly commercial vehicles. The move is appealing mainly for the system’s scalability and flexibility and expands AKASol’s customer base in the process.

According to Sven Schulz, CEO of AKASol AG, the battery system has enormous potential to promote the electrification of industrial machinery and the commercial-vehicle market even more intensively than before: “The AKARack is revolutionary due to its characteristics – it offers very high energy and power density in combination with its flexible scalability. Thus, it is the ideal solution for applications in a power range from 5 kW to approx. 50 kW. With 6.6 kWh to 40 kWh in stored energy, it is outstanding for use in industrial and construction machinery, such as small excavators or front loaders, as well as in the 48V on-board power supply system in commercial vehicles, and even for small boats.” If output of more than 50kW or even more energy is required, the 48V systems can also be operated in parallel.

See also:

China dominates battery supply chain, but Europe on the rise

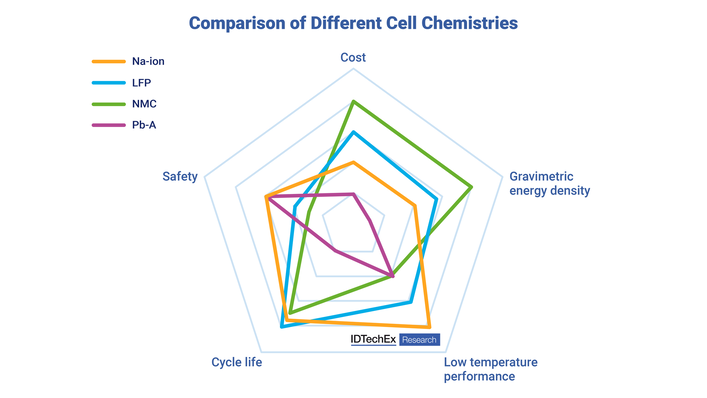

An AKARack packing 6.6 kWh of power consists of a total of three battery modules. Each battery module is constructed of twelve prismatic lithium-ion batteries (Li-ion NMC) connected in series. For particularly high-performance, up to six AKARack energy-storage modules can be connected to an AKASol Masterbox (protection, safety and voltage monitoring), which is also serial-manufactured. The AKARack is extremely robust and due to its compact design in 19-inch format (590mm x 448mm x 135mm) very easy to integrate into a wide variety of vehicles. The battery system with 6.6 kWh weighs a total of 56 kilograms and meets the requirements of protection classes IP67 and IP6K9K. The AKARack is available in either water- or air-cooled versions, depending on customer specifications.

AKASol AG

In addition to the current serial production for a globally operating construction equipment manufacturer to electrify small construction machines such as wheel loaders or compact excavators, the AKARack battery system offers an innovative application especially for the truck market. “In the last few years, the energy consumption of trucks has increased continuously, even in idle mode. While the heating and air conditioning systems in particular are among the most intensive power consumers, the data transmission of the vehicle for analysis purposes and the use of cell phones and laptops meanwhile also require a lot of energy,” as Sven Schulz explains. Expressed in specific figures, this means: With a stationary vehicle and its engine running, these systems consume up to 4.5 l of fuel per hour. This corresponds to a little less than 12 kg/h in CO2 emissions per vehicle, or up to 21 metric tons annually. “With the aid of our highly efficient AKARack, all of the energy requirements can now be met solely with the use of the battery system, so drivers can finally switch off the engine. So, the AKARack not only contributes to cost efficiency but also offers an ideal storage solution with which AKASol is now increasingly helping protect the climate, the environment and the health of our fellow human beings, even in non-electric commercial vehicles.” (mfo)