Sunovation, the specialist for building-integrated solar modules based in Elsenfeld, Germany, has developed a new collection and thus expanded the possible colour spectrum. Together with a colour manufacturer, the company has developed a new type of colour coating for the solar glass. This is based on pigments that ensure rich colour coverage with simultaneous transparency.

Sunovation uses the interference of light for this purpose. The technology is based on the fact that the sunlight hitting the module surface is split up like in a prism. The part of the light that is necessary for colouring is selectively reflected. The rest is transmitted to the solar cells to generate electricity. In this way, Sunovation reduces the influence of the colouring on the performance and efficiency of the solar cells to a minimum. Another advantage: unlike other coloured photovoltaic modules, the solar cells remain invisible in all weather conditions. The modules then also retain their coloured glass appearance from all viewing angles.

Output per area depends on the colour

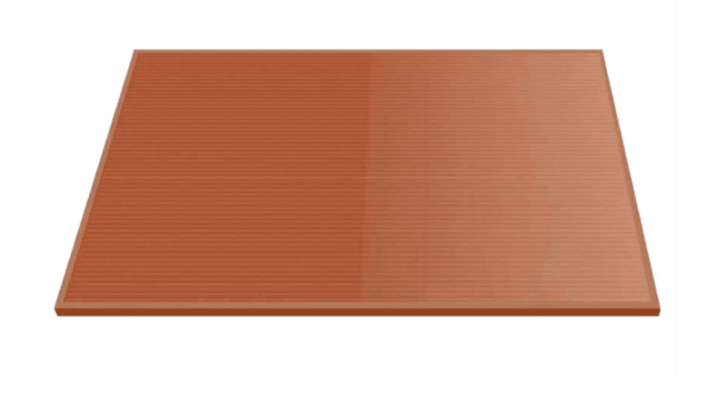

Sunovation thus not only improves the aesthetics of the modules, but also the efficiency of coloured panels. The colour collection of the new Color Quant series consists of 15 exclusive shades. The modules coated with this colour have an output of between 140 and 180 watts per square metre. Of course, this output depends on the specific colour shade. Here, too, the darker the colour, the higher the efficiency.

See also: Onyx Solar realises one megawatt photovoltaic facade

A reduction in output due to the colour scheme is physically unavoidable. The real challenge is to manage the balancing act between high output and appealing aesthetics and to reduce the undesirable influence of the colouring on the efficiency of the modules. This has been achieved with the new technology, which is now also used in the non-chromatic modules of the E-Form series.

Modules made to customer specifications

Sunovation can manufacture these modules completely according to customer requirements. For this purpose, the company uses a special process to embed the solar cells into the module. This Sunovation Cell Embedding Technology (SCET) enables the production of precisely fitting modules with individual glass structures. Sunovation can also integrate the diodes into the module and produce the cell layout according to individual requirements. The aim is always to maximise the area output of the photovoltaic modules while satisfying the customer's wishes.

As a rule, these are architects. This is because the E-Form modules are mainly used in solar facades. "In the last two years, we have seen a significant increase in demand from architects and building owners for aesthetically pleasing photovoltaic modules that can also make a relevant contribution to energy generation in the building envelope," says Heribert Ley, Managing Director of Sunovation. "The colour collection Color Quant is therefore very well received by our customers. The first facade projects with the new colour shades have already been commissioned and will be realised in 2022," he explains. (su/mfo)

Also interesting: New solution for coloured modules developed