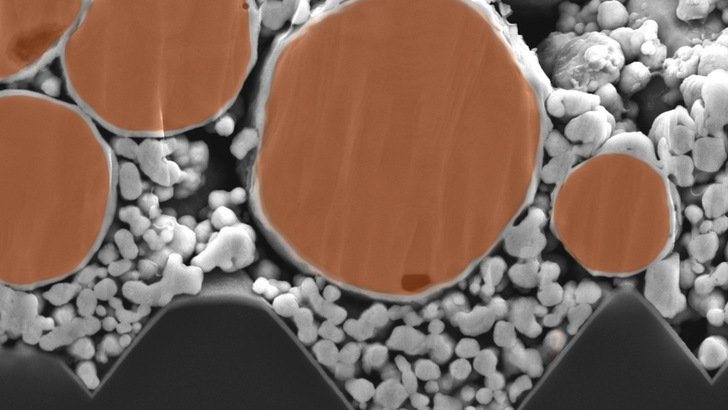

Fraunhofer ISE’s latest development marks a major step toward resource-efficient photovoltaics. To achieve this, the researchers significantly reduced the silver content in the metallisation paste for the front side and completely replaced silver with copper paste on the rear side. An optimised printing process also enabled very fine electrical contacts. The copper-metallised SHJ solar cells even achieved a higher efficiency than reference cells with conventional silver contacts.

New method improves power measurement of back-contact cells

To enable PV production on a multi-terawatt scale, solar cell and module manufacturers must significantly reduce their silver consumption. In 2024, the rapidly growing PV industry already accounted for 32 percent of global industrial silver use. To ensure long-term sustainable production, 2 milligrams of silver per watt peak has been identified as the target for global PV manufacturing.

Optimized fine-line printing process

“Thanks to the balanced combination of silver-copper paste on the front side and pure copper paste on the rear side in conjunction with an optimised fine-line printing process, we were able to produce highly efficient silicon heterojunction solar cells with a minimal silver consumption of only 1.4 milligrams of silver per watt peak,” explains Sebastian Pingel, research associate at Fraunhofer ISE.

Trends and technologies at The smarter E Europe

To optimise the composition of the metallisation pastes and the screen configurations for printing the contacts, the research team initially carried out extensive simulations using the specially developed GridMaster simulation tool. “It turned out that the selection of an optimal screen configuration plays just as important a role as the choice of the metallisation paste to reduce the silver consumption,” says Andreas Lorenz, project manager at Fraunhofer ISE. “Using novel, ultra-fine mesh screens, we were able to print a fine-line front metallisation with openings as fine as 17 micrometers, which is considerably thinner than a human hair.” (hcn)