The mood among module manufacturers at this year's Intersolar was splendid. After all, they are looking at full order books and the demand for solar modules continues to rise. In addition, they continued to work on innovations.

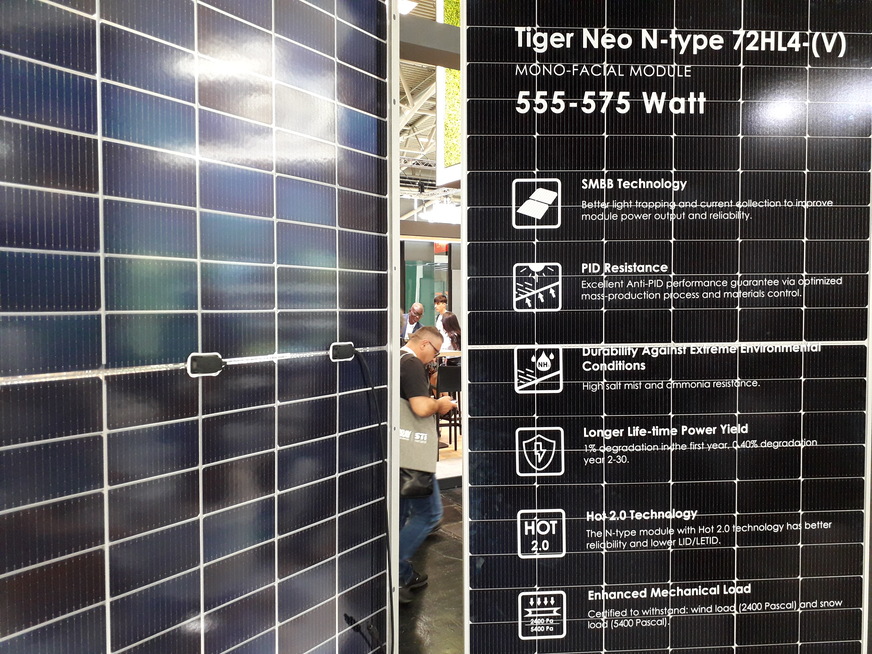

The goal: higher efficiency. The large Asian manufacturers, for example, are focusing on modules for the high-quality project segment. With the Himo 5, Longi has presented a project module with monocrystalline solar cells that reaches up to 550 watts - on an area of 2.56 square metres. That is almost 214 watts per square metre. The company relies on Perc technology and P-type solar cells.

Heiko Schwarzburger

Doped with boron and phosphorus

These are silicon cells that are doped with boron. This chemical element has one fewer electron than silicon. The top of the wafer is doped with phosphorus. Since phosphorus has one more electron than silicon, the doping is negative. The P-N junction makes it possible for current to flow in the cell.

Other manufacturers rely on N-type cells, which are built the other way around and are said to have higher efficiency - or the potential to do so. "We continue to use P-type perc cells because they are the industry standard. For the next two to three years, they will remain the optimal choice for most of our large-scale projects," confirms Jian Cui, Longi's product manager. "P-type cells not only have potential for increasing efficiencies. Above all, they are a mature technology that has proven itself in mass production."

Heiko Schwarzburger

Two cells stacked on top of each other

Jian Cui points out that Longi has consistently set new efficiency records with these cells. But the company's most recent peak performance has come with a heterojunction cell. Here, the crystalline silicon wafers are covered with thin layers of amorphous silicon.

This double cell structure achieves higher efficiency. While the crystalline part uses direct sunlight, the amorphous cell layer makes better use of indirect sunlight. The energy yield in low light is improved.

More yield from the back

The new modules from Luxor Solar are based on this technology. The bifacial glass-glass module Ecoline HTJ produces up to 480 watts on an area of 2.17 square metres.

Luxor thus achieves more than 221 watts per square metre and an efficiency of 22.38 per cent. Even if the sun only delivers 200 watts per square metre, the module achieves an efficiency of 21.88 per cent.

Good low-light behaviour brings another advantage: the bifaciality increases. The module makes better use of the light reflected from the background on the back.

Luxor also uses N-type cells. They prevent disturbing phenomena such as potential- and light-induced degradation (PID and LID), causes for long-term decreasing module performance.

Modules entirely without lead

The manufacturer REC Solar has been using heterojunction technology for some time. The new Alpha Pure is such a module. In addition, REC has eliminated the gaps between the solar cells. This allows REC to achieve an output of up to 410 watts with an area of only 1.85 square metres. That's a whopping 219 watts per square metre. REC also manufactures the new modules completely without lead, which is why the company won one of the Intersolar awards.

Heiko Schwarzburger

IBC Solar, among others, relies on another technology. The new module from the Franconian company is equipped with Topcon cells. Topcon stands for Tunnel Oxide Passivated Contact. This technology is also based on N-type cells with additional p-doped layers. Between the silicon base and the p-doped layer, a layer of silicon dioxide is applied, which acts as a tunnel oxide.

This tunnel oxide acts like a lift for the electrons into the p-doped outer layer. From there, they travel to the passivated rear contact. This reduces the losses within the solar cell, increasing efficiency and output.

Easy changeover

Topcon's advantage lies in mass production. "Compared to the previous mono-perc cells, cell manufacturers only have to add two more manufacturing steps to their production lines," explains Thomas Bartsch, Head of Product Management at IBC Solar. "This makes the switch to the new technology relatively easy. After all, it's just a matter of an additional treatment of the wafer surface."

Which technology will prevail in the market remains to be seen. IBC Solar also has monocrystalline modules with Perc cells and heterojunction modules in its portfolio.

Half cells are standard

However, the company is currently focusing more on Topcon technology. "For cell manufacturers, the switch to heterojunction technology means more effort than to Topcon," says Bartsch.

Because of the growing wafer sizes up to M10 or M12 and the lower internal resistances, half-cell modules have gained acceptance. In them, the electrons have to travel shorter distances, which increases efficiency.

Heiko Schwarzburger

In addition, the modules are usually divided into two or three separately functioning parts. This makes them less susceptible to shading.

M10 as a standard for module size?

Basically, module manufacturers are currently faced with the question of which cell size will prevail in the medium term. For example, Longi uses M10 solar cells with an edge length of 182 millimetres for new modules. Previously, 166 millimetres (M6) was considered the standard.

Whether this is the end of the line is not certain. That is why the Sonnenstromfabrik has opted for more flexibility. The company will launch its new module series with heterojunction cells this year, initially with M10 cells. "In the long term, we will move towards a cell format of 220 millimetres edge length," predicts managing director Bernhard Weilharter. The machine park of the company from Wismar is equipped for this. The largest module of the new series has a surface area of 2.4 square metres.

See also: Sharp’s M10 half-cell solar modules with up to 410 watts

With the new Vertex module, Trina Solar has a panel on the market with an area of almost 3.11 square metres. The weight of the module rises to 33.9 kilograms, hardly manageable for a craftsman. After all, the module has an output of 670 watts.

Adjusting the mounting technology

Heiko Schwarzburger

It is not only the weight that can become a challenge in projects. "Especially in the commercial systems segment, the mounting systems have to be adapted," explains Thomas Bartsch from IBC Solar. "With increasing module sizes and the trend towards thinner frames, deflection of the modules in snow and wind becomes a challenge." These loads can only be absorbed by the mounting system.

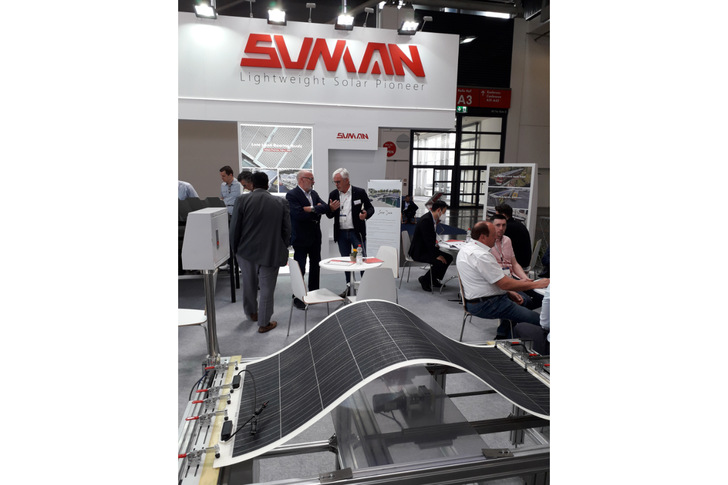

Modules entirely without glass

The alternative is lightweight modules, such as those produced by Sunman in China, soon to be produced in a new factory in Europe. These modules do not need any glass at all, which drastically reduces their weight. This makes them particularly suitable for commercial roofs with low load reserves.

Sunman has also developed a new module series and presented it in Munich. "We have switched to the larger cells and have developed a half-cell module with 430 watts of output," confirms Sales Manager Matthias Schoft. The modules have grown somewhat as a result.

Up to 560 watts

Sunman already has its eye on the next step. "The cell sizes will continue to increase, we are already preparing the next module sizes," Schoft holds out the prospect. "Then the output will increase to 560 watts. This will probably be the case by the end of the year."