Perovskite photovoltaics (PV) continue to generate excitement across the solar industry for their high efficiency, low-cost materials and scalable production methods. But commercial success depends on more than just lab performance.

Durable, scalable and efficient?

Commercial silicon solar panels typically last 20 to 25 years, setting the standard for competing photovoltaic (PV) technologies. To keep pace, alternatives like perovskite PV must show they can also go the distance. While durability challenges have long held back commercialisation, several pilot and small commercial-scale projects are now underway. Many companies are achieving panel lifetimes beyond 10 years and steadily narrowing the gap to the 25-year target. But what material advances have enabled this progress in extending perovskite PV device lifetimes?

Severe impacts of degradation

Under real-world conditions, PV modules face constant exposure to intense sunlight, humidity, rain and extreme weather. To maintain performance over time, they must withstand these stresses with minimal degradation.

Perovskite – the next major solar technology?

Perovskite PV devices have long struggled with stability under atmospheric conditions, limiting market adoption and raising doubts about their reliability. However, recent strides in materials science have greatly improved their durability, paving the way for commercialisation.

Perovskite solar cell degradation falls into two main categories: intrinsic and extrinsic. Intrinsic degradation is linked to material defects and ion migration, while extrinsic degradation is driven by environmental factors like heat, moisture, oxygen and UV radiation. Both can seriously affect the cell’s electronic and optical properties, triggering chemical changes and structural shifts in the perovskite film.

IDTechEx

To boost long-term durability, researchers have focused on improving intrinsic stability through material engineering. This includes adjusting chemical compositions to increase resistance to ion migration, enhance crystal stability and reduce defect density. Alloying at either the A-site cation or X-site anion can help relieve strain and distortion, or fine-tune the material’s bandgap, respectively.

Tailwind for the commercialisation of perovskites

While these modifications improve stability, they can also affect optical properties and reduce light absorption. Striking the right balance between durability and performance is essential – but external encapsulation offers a way to minimise this trade-off.

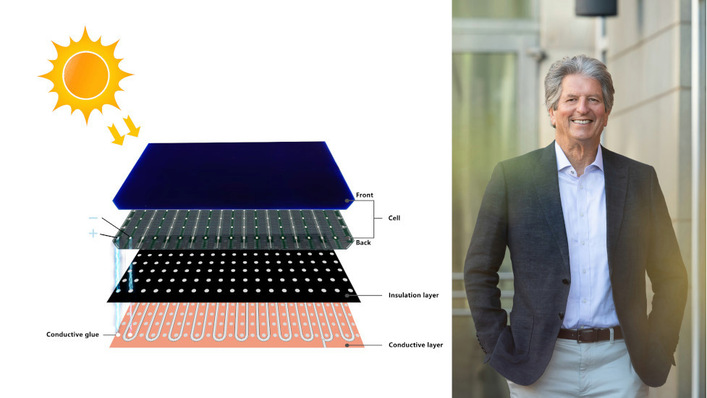

High-quaility encapsulation as an effective measure

Advanced encapsulation continues to be among the most effective ways to enhance perovskite-PV longevity without compromising PCE. In particular, glass–glass sealing—a proven technique in silicon modules—encloses the cell between two glass layers, ensuring robust environmental protection.

This approach is especially well suited to rigid perovskite–silicon tandem devices, where it has already shown decades of projected durability in traditional silicon panel applications. While exact encapsulant details remain undisclosed, companies such as Tandem PV have reportedly demonstrated lab results equivalent to decades of performance, and Oxford PV’s tandem panels have reportedly passed all key IEC reliability tests.

Market launch of perovskite-silicon tandem solar cells expected in the near future

To enable flexible and thin-film devices, polymer encapsulants or emerging thin-film materials may be used. Polymer encapsulants have been widely studied and are already commercially available for use in OLED devices. Ethylene vinyl acetate (EVA) remains the most common encapsulant in the PV industry, thanks to its long-standing role in silicon module production.

Is a 25 -year lifetime necessary?

It is cheap and has good optical transmittance; however, it is known that acetic acid can be released over time as a chemical by-product, which degrades the efficiency. Additionally, its water vapour transmission rate (WVTR) is considered too high for perovskite solar cells, allowing for water ingress and degradation to the cell. Alternative polymers, such as polyisobutylene (PIB) and butyl rubber show promise, although they have been less extensively studied.

Perovskites will enable new applications for photovoltaics

Thin-film encapsulation is an emerging alternative for flexible device fabrication. Materials such as aluminium oxide, tin oxide, titanium oxide, silicon oxide and silicon nitride have already been tested in OLED manufacturing and are compatible with existing production equipment, supporting scalable manufacturing for perovskite PV.

In a fast-moving technological landscape, is a 20- to 25-year lifetime still essential? Residential silicon solar panels typically achieve a return on investment (ROI) within 8 to 12 years of their 20- to 25-year lifespan. As long as the ROI period remains well below the technology’s lifetime, perovskite durability may be less of a concern.

Companies such as Power Roll have developed a novel device architecture that is roll-to-roll compatible and offers significantly lower manufacturing costs than silicon solar. Their modules have a projected lifetime of 10 to 15 years, with the company targeting a 2- to 3-year ROI – making them an appealing option for fast-moving, technology-driven markets.

See the IDTechEx report for more information

Perovskite PV’s reputation for fragility is beginning to shift. Durability remains a critical metric, but thanks to ongoing advances in materials science and encapsulation, the technology is increasingly ready for commercial environments. Several products are already on the market, and broader adoption looks increasingly within reach. (Maia Benstead/hcn)