On bright days, aircraft approach the airport at low angles of around 10 degrees, turning the flat surface of solar modules into dangerously reflective mirrors. As a result, Schiphol has paused landings on one runway and announced the removal of 78,000 of the 230,000 solar panels from a nearby installation.

This incident underscores a growing challenge: as solar energy systems become more widespread, especially near infrastructure such as airports or roads, glare management goes beyond a design concern and is a safety‑critical issue. Conventional solar panels, even those with anti‑reflective coatings, often cannot meet the strict requirements of glare‑sensitive zones. Addressing this need, SoliTek has introduced a next‑generation solution that raises glare control to a new level without compromising longevity or performance.

BER: Berlin Airport is getting three solar roof systems

New matte-glass technology

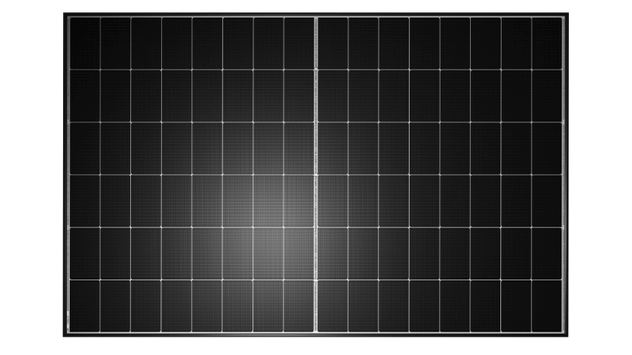

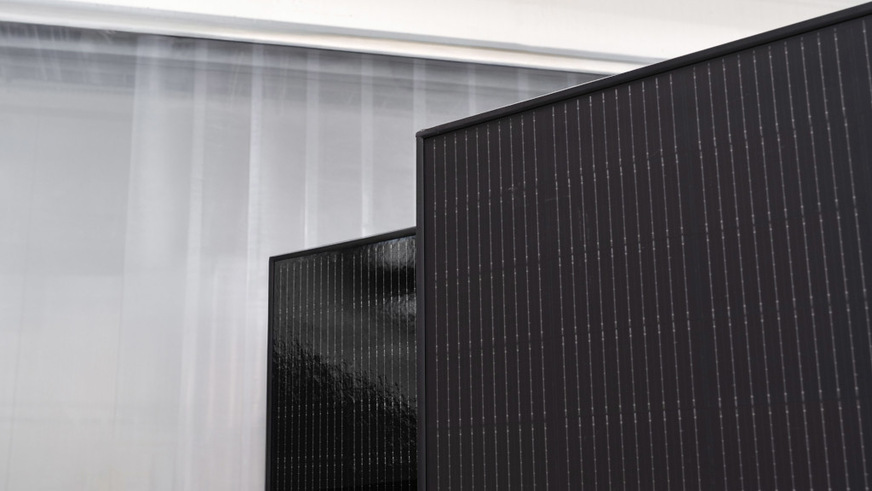

SoliTek’s new generation of full‑black solar modules features matte, structured front glass, a surface engineered to reduce reflectivity and meet the highest optical safety standards. Instead of a coating, SoliTek uses structured glass, a permanent surface texture that diffuses sunlight without degrading over time. This provides the modules with long‑term optical stability, UV and humidity resistance, and exceptional glare control.

Solitek

In glare testing, the new module achieved just 4,000 cd/m² luminance at a 10° incident angle, less than half of the commonly accepted 10,000 cd/m² limit for low‑glare applications and well below the levels seen in standard modules. Even at 20°, luminance remains at 5,000 cd/m². At steeper angles, luminance increases (for example, 31,000 cd/m² at 60°), but these cases are less relevant, since low‑angle light poses the greatest risk, particularly for pilots during descent or drivers passing roadside PV installations.

Minor reduction in nominal outpout

This glare performance comes with only a minor trade‑off: due to the light‑diffusing structure of the front glass, nominal output is reduced by about 2.3 percent, resulting in a 425 W module instead of the usual 435 W. For airports, façades, noise barriers and visually or safety‑sensitive areas, however, the gains in durability, aesthetics and regulatory compliance far outweigh this small loss in peak performance.

Increasing requirements for solar modules

SoliTek offers the matte‑glass technology across its key product lines, including framed and frameless bifacial glass‑glass modules as well as roof‑integrated Solrif systems. It is an ideal solution for airports and airfields, but also for building façades, transport infrastructure, residential zones in Switzerland and Germany, agrivoltaics and protected nature areas – anywhere solar energy must coexist with safety, architecture or strict visual requirements.

As solar becomes more integrated into cities, landscapes and critical infrastructure, smart materials such as SoliTek’s satin glass are redefining what a solar panel can do – not only generate clean energy but also protect its surroundings. (hcn)