The company Aero-Lift specializes in lifting and handling equipment for the renewable energies sector. It offers smart solutions for its partner companies such as solar installers, plumbers and heating engineers. Particularly when it comes to separating photovoltaic modules for the respective customers and installation teams, the need for supporting solutions is increasing. Several deliveries are to be handled every day.

In the manual handling process, at least 2 people are required here due to the weight of the individual modules and in order to protect the material. There is a risk that one of the unwieldy modules could fall and break. Another aspect is ergonomics. These were all reasons enough for the PV provider ezee Energy to think about optimizing the workflow. With specialist company Aero-Lift next door, it was obvious to knock on the door of the specialists for vacuum technology.

Transport up to six solar modules at the same time

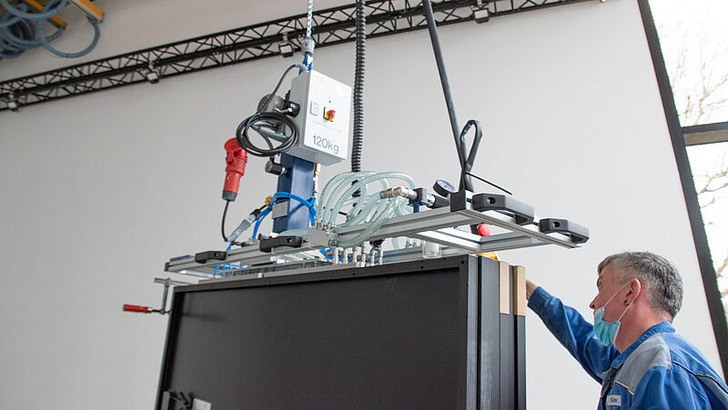

After analysing the existing work process, the engineers at Aero-Lift developed a special solution for the PV industry. With the Aero 135/12M-SK, several photovoltaic modules simultaneously can be picked up and can, for example, be precisely removed from or inserted into cardboard boxes. Thanks to the soft, flexible seals of the suction plates, the modules are safely secured and can be transported from A to B without damaging the material.

See also: Trend paper: PV mounting systems

Aero-Lift

The distance between the individual suction plates can be adjusted. Conversion to solar modules of different widths is therefore carried out in no time at all. For common sizes, there are also special positioning aids that make the changeover even more convenient. Each suction plate row can be manually shut off individually via a manual slide valve. This means that one to six modules can be handled with the same setup.

Up to date safety standards and accident prevention

The units are designed and manufactured in accordance with the latest safety standards as per EN 13155 and ASME B30, and are tested and documented in accordance with the applicable accident prevention regulations BGR 500 and Machinery Directive 2006/42/EC/Annex IIA. The final acceptance test is carried out according to VDE 0113 and EN 60204.

Also interesting: Enviria and Q Energy to build 500 megawatts of solar park capacity in Germany

Aero-Lift also has a solution for swiveling modules: By means of Aero 125/4R 90°/1800 the solar panels can be rotated by 90° and transported horizontally as well as vertically. Thus, it is also possible to efficiently move individual modules.

Thanks to a mobile light gantry crane, the picking stations at ezee Energy can be flexibly relocated in the halls without requiring any structural measures. The formerly tiring and unliked picking work can now be done more comfortably, faster and more efficiently, above all by just one person. (mfo)