Electrolyser manufacturer Quest One has begun construction of a demonstration plant for its Modular Hydrogen Platform (MHP) PEM electrolyser in Augsburg. The unit will be installed in a test stand at the Turbocharger Performance Center (TPC) on the Augsburg site of MAN Energy Solutions (MAN ES), where it will generate data in test operation for continuous optimisation.

The new demonstration plant from Quest One is designed to make large‑scale electrolysers a more tangible and accessible concept. As such systems are seldom available for inspection at customer sites, the project will open a dedicated facility where they can be assessed directly. From mid‑2025, potential customers, project developers and EPCs will be able to visit the plant in Augsburg and gain structured insights into its construction phases, dimensions, inner workings and infrastructure.

Work begins on extending European ElyLab electrolysis test site for strategic technologies

A second objective of the joint project with MAN Energy Solutions is to optimise the scaling of PEM electrolysers using field data and to refine system operation together with installation and service concepts.

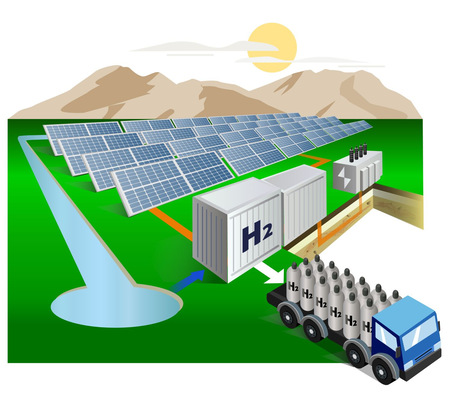

Suited for use with renewable energy sources

“It’s essential to have industrial‑scale electrolysers to meet the huge demand for green hydrogen in the future. With our new hydrogen demonstration plant we will show that the technology for industrial‑scale hydrogen production already exists. In particular, our PEM electrolysis technology is perfectly suited for use with renewable energy sources and stands out with a high hydrogen quality. Prospects can now experience these advantages at our demonstration plant,” says Jürgen Klöpffer, chairman of the advisory board of Quest One and member of the executive board of MAN Energy Solutions.

Spain: 1.5 GW green hydrogen projects of DH2 Energy in Extremadura

“Our MHP is an essential building block for decarbonissing of the industrial sector. The scalable system can be flexibly adapted to increasing hydrogen demands as the industry ramps up. The demonstration plant is an important means for us to further optimise the performance and operating parameters of the MHP. This will ensure that our products continue to produce green hydrogen in a reliable and efficient way in the future,” explains Michael Meister, COO at Quest One.

Joint project implementation

The project highlights the joint efforts of Quest One and MAN Energy Solutions to establish green hydrogen as a reliable fuel for industrial decarbonisation. Through the jointly operated test stand, the partners are expanding expertise in construction, project management, operation and maintenance of large‑scale industrial electrolysers. Quest One is also taking another step in scaling its portfolio for projects from 10 MW to several hundred MW of electrolysis capacity. Expanding capacity remains a key prerequisite for the company’s goal of avoiding up to one percent of global greenhouse gas emissions by 2050 through the use of its products.

Norway - EnBW starts marketing process for green ammonia

Construction began at the end of 2024 with installation of the freshwater treatment. The plant will be assembled during 2025, with test operations scheduled to start at the beginning of 2026. Potential business partners will be able to gain insights into the construction phase and visit the plant on site in Augsburg in 2025.

Industrial-Scale hydrogen production

The MHP is currently the largest PEM electrolyser in Quest One’s portfolio. Its scalable modular system makes it well suited for industrial production of green hydrogen. Module blocks with an output of 10 MW can be expanded and combined to create plants with an electrolysis capacity from 10 MW to several hundred MW. The system is optimised for straightforward indoor installation on preassembled skids. Each 10 MW block includes integrated process water treatment and an electrical power supply.

Funding under the PEP.IN program

The development of the demonstration plant is being funded under the PEP.IN research project, a sub‑project of the H2Giga hydrogen lighthouse programme of the German Federal Ministry of Education and Research (BMBF). PEP.IN is exploring new processes for the series production of PEM electrolysers, covering the entire value chain from stack production to final assembly. The aim is to make green hydrogen affordable and competitive. The funding particularly addresses feasibility and viability studies as well as planning of the necessary infrastructure. (hcn)