Selecting the right components

Before crimping, materials must be carefully matched. It is essential that connectors, cables and tools are compatible. When selecting the connector, pay attention to:

– dielectric strength

– current carrying capacity

– operating temperature

– conductor cross-section

Only once these are defined should the appropriate solar cable be selected for the application.

EMC-direct – wiring systems correctly and safely

Tools: Quality over compromise

Your tools must be suited to both the cable cross-section and the connector. Use only:

– Certified stripping tools that automatically adapt to the cross-section and avoid damaging strands

– Approved crimping pliers, ideally with a ratchet that releases when the correct crimping force is applied

Avoid using general-purpose crimping pliers without manufacturer approval – especially in PV installations, where safety requirements are high.

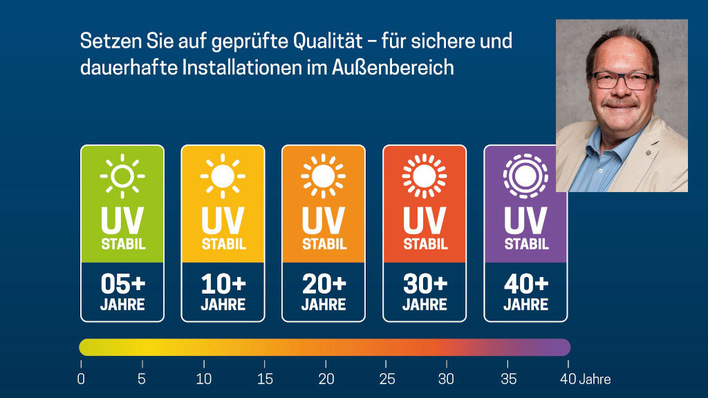

EMC-direct: Don’t underestimate cable UV resistance

Stripping: Only bare conductors may enter the sleeve

Strip the cable to the correct length – usually 7 to 10 mm, depending on the connector. Ensure that you:

– Do not damage or cut strands

– Briefly twist strands to check for damage

– Re-strip if insulation was removed incorrectly – damaged conductors can cause higher resistance and increased fire risk

Crimping: Positioning and execution

Insert the conductor fully into the centre of the crimp sleeve. Important points:

– Only the bare conductor should be crimped – never the insulation

– Ensure straight, parallel insertion into the tool

– Press the pliers through until they release automatically

Poor alignment or an incomplete crimp can lead to thermal stress, contact loss or arcing.

EMC-direct – these installation faults are easily avoided

Quality control – the final and most important step

A good crimp is identified by:

– All strands fully and evenly crimped

– A symmetrical, firm, glossy crimp – a sign of correct pressure

– No loose wires or insulation residues in the crimp area

Also check that the contact point is clean and free of defects. This is essential for a reliable, mechanically strong connection.

Crimping is precision work – with consequences

A poorly crimped connector may seem harmless, but it poses significant risks: from power loss and fire hazards to partial system failure. It pays to invest in certified tools, trained personnel and high-quality materials. (AD/TF)

Author Arnd Dietrichs is Head of Product Management and Purchasing at EMC-direct and an expert in tool development. The company's solutions for cable protection and fastening are used in large-scale solar projects in Austria, Denmark and beyond.