Careful selection of materials is especially important in industrial or coastal areas. If no specific environmental requirements apply, the following standards are recommended:

· Standard black cable ties offer a UV resistance of around three years and are unsuitable for photovoltaic systems.

· For installations in Central Europe and the Mediterranean, the use of cable ties made of UV-stabilized polyamide 6.6 is recommended, such as HPER cable ties with a tested UV resistance of ten years.

· For subtropical or alpine requirements, cable ties made of polyamide 11 or stainless steel (service life of more than 40 years) are recommended.

EMC-direct: These installation faults are easily avoided

Alongside this basic advice, it is strongly recommended to request the technical data sheets of the cable ties from suppliers, and in particular to carefully check the information on UV resistance. Regretably, it is common practice in the industry to use conventional cable ties with a UV resistance of only three years, but that does not mean that you have to make the same mistake

Part of the integrated cable management system

No integrated cable management system can do without cable ties. Here too, it is possible to avoid simple installation errors. For example, even high-quality cable ties should never be fed directly through a laser-cut fastening hole in module frames. Here, the use of edge clips protects against material damage and incorrect loading.

EMC-direct: Secure cable routing prevents later damage

Avoid contact corrosion

When installing edge clips and other fastenings on the aluminium profiles of solar modules, it is not only UV resistance that to be considered but also protection against contact corrosion. This is when different metals come into contact, such as steel clips and aluminium frames. If that‘s not enough, moisture also has an aggravating effect and can subject aluminium to wear, resulting in material damage and sharp edges, and ultimately in damaged or highly brittle cable insulation.

The solution: high-quality clips have special coatings that prevent direct contact between metals. Check the data sheets for corresponding specifications to ensure long-term safety.

EMC-direct: Knowing and avoiding fire risks in solar fields

Thermowells: Safety when laying cables

Several factors should be considered when selecting suitable cable protection pipes, including UV resistance, fire protection, pressure resistance and mechanical water resistance. Long-term UV-resistant corrugated pipes made of PP plastic are ideal for above-ground installation. These are lightweight, flexible and resistant to UV light for up to 20 years, and are available in slotted, non-slotted and two-piece variations.

EMC-direct: Wiring systems correctly and safely

Rigid or flexible pipes of HDPE plastic are the best choice for underground installation in ground-mounted systems. UV-resistant special versions even offer universal hybrid solutions. Note: Unsuitable flush-mounted pipes such as black FBY pipe without UV resistance, which pose a high risk to the cables in the system, are all too frequently used in place of more appropriate components. These pose a high risk to the cables in the system, and users should check technical specs well – and well in advance.

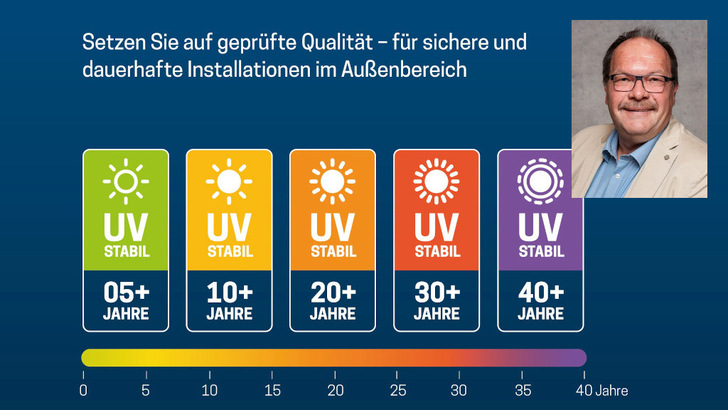

UV-stable label: Clarity for reliable planning

The UV-stable label from EMC-direct provides planners, architects and installers with clear guidance. It only applies to components with proven long-term UV stability, ensuring consistent quality even after years of exposure to intense sunlight. The advantage is that every label clearly indicates how many years UV protection is guaranteed – aiding in efficient and reliable project planning. (HS/TF)

EMC-direct: Human factor behind high costs

Free white paper for safe and secure operation of facilities: The specialists and EMC-direct have put together the white paper “Knowing and avoiding common causes of damage to photovoltaic systems” to raise awareness of high quality standards in the assembly and electrical installation of PV systems. Download the free white paper here (German)

Author: Frank Mazur is head of sales at EMC-direct and an expert in cable management and cable protection in photovoltaic systems. His team has worked on major solar projects in Austria and Denmark using products from EMC-direct, a leading supplier for cable protection and fastening technologies based in Dorsten, Germany.