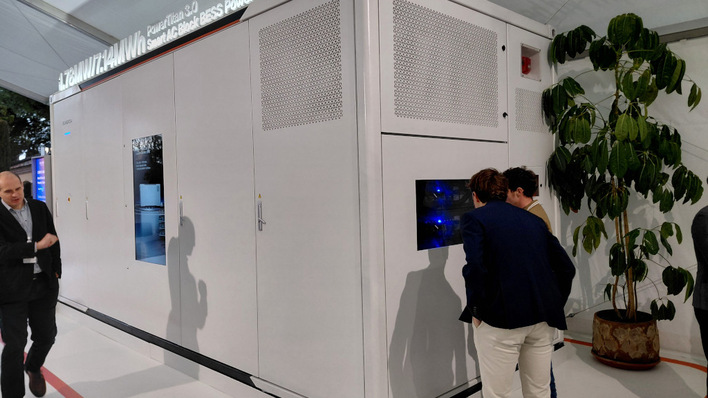

First place went to the Primo GEN24 6.0 Plus for the 5 kWp reference case, while the Symo GEN24 10.0 Plus came in second for the 10 kWp reference case. Fronius was also the only inverter manufacturer to manage this with both products in energy efficiency class A.

The HTW Berlin Energy Storage Inspection is a study carried out annually, involving an industry-wide comparison of PV storage systems for private households by independent institutes. This year, 20 energy storage systems from 15 manufacturers competed against one another and were evaluated using the System Performance Index (SPI).

Highest SPI in the 5 kWp reference case

“We are pleased to achieve such an outstanding result in the Energy Storage Inspection again. This independent evaluation is a fantastic source of energy-efficient storage solutions for installers and end customers. It shows us that ongoing optimization of our products is paying off and is encouraging us to continue with this approach,” says Martin Hackl, Global Director of the Business Unit Solar Energy, Fronius International GmbH. “The high system efficiency means lower energy losses, which in turn leads to higher yields and the system paying for itself more quickly,” he continues.

See also: LG signs contract with carbon-free lithium producer from Germany

The Primo GEN24 6.0 Plus together with the BYD Battery-Box Premium HVS 7.7 achieved the highest SPI in the 5 kWp reference case. At 92.2%, the hybrid inverter came in a whole percentage point ahead of the runner up. In the 10 kWp reference case, the Symo GEN24 10.0 Plus with BYD Battery-Box Premium HVS 10.2 improved upon last year’s result by 0.6%, taking it to an SPI of 94.6%. “Although we already came first last year, we looked closely at the optimization potential and set about making it a reality. As a result, we came out on top once again and improved the performance. This is due to the high conversion efficiency, made possible by the use of silicon carbide (SiC), and also the excellent collaboration with BYD,” explains Product Manager Susanne Lampl.

Success factors: Multi Flow Technology, silicon carbide, and strong partners

Multi Flow Technology – the intelligent management of energy flows and a factor in the device’s success1 – not only permits simultaneous energy flows in all directions, but also AC and DC coupling of the battery storage. The power electronics provides the basis for this. Very high conversion efficiency can be achieved through the use of silicon-carbide-based power semiconductors, even in the case of low utilization of several hundred watts. This has led to a sustainable change in Fronius inverters.

Also interesting: Fronius is expanding its portfolio

Fronius and Chinese high-tech company BYD formed a strategic partnership over four years ago. “Thanks to this excellent collaboration, we can respond to market requirements quickly and effectively and offer high-quality solutions,” say both Julia Chen, Global Director, BYD Battery-Box and Martin Hackl. (mfo)