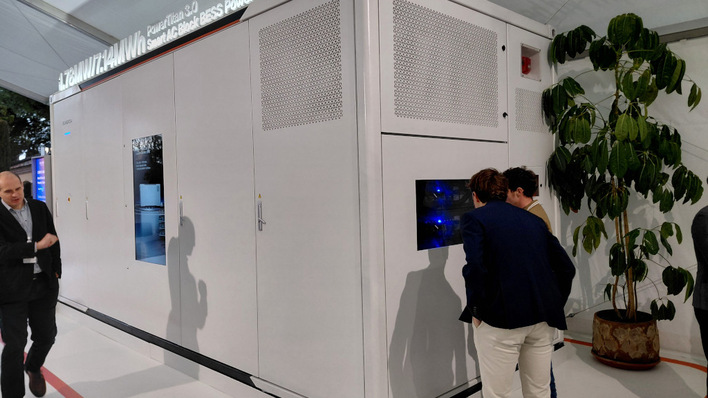

The system consists of four battery containers that can hold around six megawatt hours. The discharge capacity reaches up to one megawatt. The sodium-sulphur batteries can provide electrical energy for six to eight hours.

Stay up to date, sign up for our investor newsletter!

BASF takes over distribution for NGK Insulators

They are distributed by BASF subsidiary Stationary Energy Storage. They are built by the Japanese company NGK Insulators. The storage units are expected to be in operation by the end of this year.

Sodium-sulphur batteries have been installed worldwide for more than 20 years, so far in around 250 projects with a total of 720 megawatts of connected load and 4.9 gigawatt hours of storage capacity.

Around 79 per cent efficiency

Unlike lead-acid batteries or lithium storage, NaS batteries have a solid electrolyte (aluminium oxide containing sodium). On the other hand, the electrodes are liquid: The anode consists of molten sodium. Graphite fabric impregnated with liquid sulphur acts as the cathode.

See also: Fraunhofer FFB looks into opportunities for sodium batteries

To operate, the storage unit must be heated to 270 to 350 degrees Celsius, which is why the round-trip efficiency only reaches about 79 per cent (lithium systems: 96 per cent).

Comparable energy density

The energy density of NaS storage units and lithium storage units is roughly the same. However, the basic materials for NaS systems are more readily available, which is why they can be more cost-effective, especially in industrial use.

Also interesting: Storage offers more possible business models for investors

In Schwarzheide, BASF produces various basic products for polyurethanes, crop protection agents, water-based coatings, engineering plastics, foams and battery materials. About 2,100 employees work at the plant. (HS/mfo)