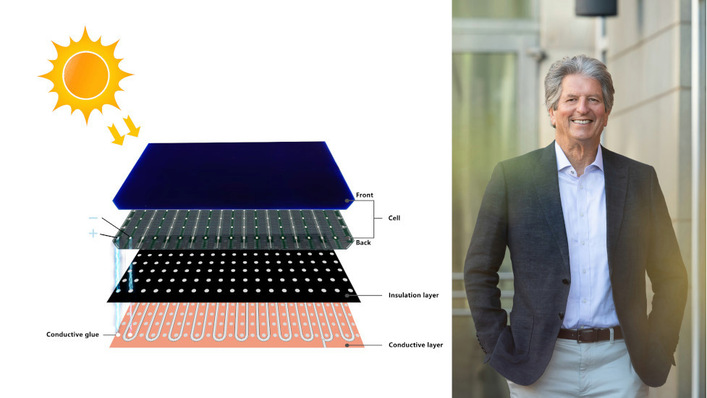

The “Matrix” architecture, debuting in a serial module for the first time, offers up to 90% higher yields under the same conditions, including partial shading, compared to traditional modules. Developed in collaboration with two Fraunhofer institutes and various vehicle manufacturers, these innovative panels are set to be produced at Opes Solar Mobility's new facility in Zwenkau, Germany, starting this autumn.

Significant benefits for diesel-powered commercial and recreational vehicles

The new solar panel is ideally suited for the growing field of e-mobility in logistics and camping. At the start of production, the primary focus will be on conventional diesel vehicles with larger roof surfaces.

Trends and Technologies at The smarter E Europe

Modern commercial and recreational vehicles are increasingly equipped with main and auxiliary electrical consumers, such as refrigeration units, liftgates, and air conditioning systems. These are currently powered by the diesel engine or the alternator, which increases fuel consumption. With photovoltaic panels installed on the vehicle roof, solar energy can now supply these electricity-consuming devices, thereby reducing the load on the alternator or engine. This meaningfully lowers operating costs and CO2 emissions.

Smarter E AWARD 2025: Energy Transition pioneers shortlisted

“Photovoltaics on commercial vehicles is not an eco-niche but economically viable. Even light commercial vehicles equipped with 800 watts of solar power can achieve fuel savings of up to 9%. We estimate the market potential in the EU at over 20 GW of solar capacity annually,” says Robert Händel, CEO of Opes Solar Mobility.

A standard semi-trailer, for example, can generate up to 5 kW – equivalent to the output of a typical residential rooftop system. At the same time, battery life is extended and deep discharges can be prevented.

Technology mix solves key challenges simultaneously

Solar modules on vehicles are continuously subjected to vibrations and shocks, and they experience heavier dirt buildup than conventional stationary solar systems. In addition, they are constantly exposed to changing shading conditions. O.Motion combines various technologies to address these challenges.

The core innovation lies in the newly developed Matrix architecture, where solar cells are arranged in a masonry-like pattern. Unlike traditional modules that rely on soldered busbars, the cells are interconnected using a highly conductive specialised adhesive for electrical contact, eliminating the need for ribbon soldering.

Germany still leading the way in e-mobility

The matrix minimizes resistance losses and maximises the active cell area per square meter. Compared to conventional flexible modules, this allows up to 30% more output on the same surface. Reduced sensitivity to shading further enhances energy yields under real-world conditions.

The new adhesive connections provide not only excellent electrical conductivity but also exceptional mechanical durability – a crucial advantage for mobile applications subject to vibrations and high temperatures. With this, O.Motion sets new standards for flexible, high-performance solar panels in the automotive sector, claims the company. (hcn)

Don‘t miss our pv Guided Tours and CEO Talks – LIVE from Munich