The new measurement method uses photoluminescence and contactless electroluminescence imaging under varying excitation conditions, along with spectral reflection measurements. Combined with a model, this enables derivation of the full current-voltage (IV) characteristic curve and key performance parameters such as open-circuit voltage, short-circuit current density, fill factor and efficiency.

Contactless power measurement is particularly advantageous for solar cells that are difficult to contact, such as back-contact solar cells. It also reduces the risk of damage to increasingly thin cells and can shorten measurement time during manufacturing. In addition, it supports higher production rates, helping to lower investment costs when setting up new production lines.

Further adjustments for use in industrial mass production

“The results of conventional contacted measurement and the new contactless measurement method show very good agreement in our tests,” says Dr. Johannes Greulich, group manager for inline solar cell analysis and simulation at Fraunhofer ISE. “We intend to develop the adjustments required for use in industrial mass production and accelerate the measurement of the reverse behavior in a future research project with partners.”

SolarPower Europe: High potential of European PV manufacturers

New efficiency records for silicon solar cells have been achieved in recent years with IBC cell architectures, with the current record of 27.8 percent also held by a back-contact solar cell. As both metal contacts are located on the rear side of this design, the cells must be contacted from one side for quality control – a process that requires special equipment and significantly limits throughput due to its complexity.

Next-gen solar cells

“Our contactless method is therefore particularly suitable for measuring these single-sided metallized solar cells as well as the bottom cells of perovskite-silicon tandem solar cells, which have no contacts at all,” adds Johannes Greulich.

Trends and technologies at The smarter E Europe

Director Ralf Preu: “The inline-capable, contactless solar cell power measurement methodology opens the door to productivity increases of more than 10,000 wafers per hour and to the production of even thinner solar cells. With this innovation, we are enabling more cost-efficient large-scale production of next-generation solar cells.”

EU PVSEC 2025 prepares to unveil future PV technologies

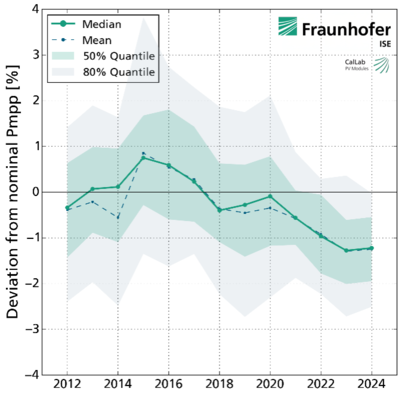

As part of its PV-TEC research line, Fraunhofer ISE operates an automated solar cell tester that enables both contacted IV measurements and contactless measurements on solar cells up to G12 format (210 mm × 210 mm), as well as on shingle solar cells in high volumes. In its latest study, the research team measured 150 IBC solar cells with varying efficiencies using both the contactless method and the conventional contact approach with a flasher from halm elektronik GmbH, then compared the results. (hcn)