The beginning of 2025 saw violent storms sweep across Western Europe, continuing a recent trend of extreme weather events, raising important questions about heightened stability demands for solar roof installations.

Wind and snow present significant challenges for solar roof systems, unlike ground-mounted installations. “In terms of wind loads, this does not mean that the average wind speeds are increasing. It's more about the frequency of events such as thunderstorms, and hese are usually unpredictable,” says Cedrik Zapfe, CTO of the Schletter Group, a manufacturer of mounting systems.

Protecting solar plants in extreme weather

Rising wind extremes challenge solar roof stability

He highlights the increase in powerful winds, such as tornadoes, in recent years. “Including a tornado in the planning is neither possible nor sensible,” he says. “Because if you wanted to implement a tornado design, the substructures would be incredibly heavy and massive, making it economically unfeasible – apart from the fact that the roofs would reach their limits rapidly with their residual load-bearing capacity. In such cases, you have to accept the residual risk.”

A tornado not only increases the load but also exerts entirely different forces compared to normal wind. Typically, winds pull photovoltaic installations both upwards and horizontally, countered by their own weight and ballasting. As wind speeds rise, the required ballasting must increase disproportionately. “If the wind speed increases by ten per cent, the load affecting the system increases by 21 per cent,” explains Cedrik Zapfe.

Compliance with applicable standards

This principle applies only to normal winds with a high harmonic proportion and minimal turbulence. In contrast, a tornado generates significantly more turbulence, causing wind forces to act on the roof in entirely different ways. While turbulence can also be triggered by underflows and overflows in normal winds, these forces are far weaker than those of a tornado, making advanced planning an almost impossible challenge.

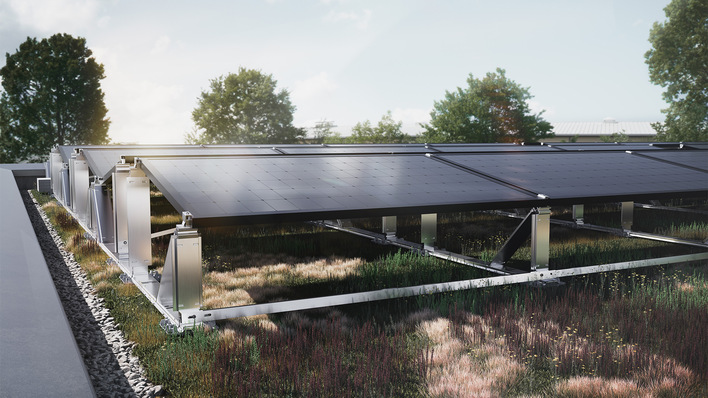

Sleek and efficient modules for solar roofs

Cedrik Zapfe advises adhering strictly to applicable static standards, which define the wind and snow load values required for the static calculation of photovoltaic systems in each region. “The consequences of climate change are already factored in,” says the Schletter expert.

While wind and snow load zones encompass vast areas, winds do not behave uniformly across these regions. Consequently, additional buffers must be planned to account for locations within the zones that experience stronger winds. Furthermore, Eurocode 1, the standard applicable across Europe, is updated every three to five years. These updates impact not only photovoltaic systems but also the broader construction industry, which operates with the same wind and snow load values.

Avoiding planning errors

The standards consider not only the region where the system is located but also its surrounding environment. Buildings situated in open landscapes or on the outskirts of towns are subject to higher estimated wind loads compared to those in built-up areas. “The problems lie in borderline cases and grey areas: In practice, it happens repeatedly that systems are planned and calculated in a risk class that is too low for cost reasons. In the event of damage, no insurance will pay,” warns Cedrik Zapfe.

Vaisala Xweather launches advanced hail forecasting

If systems are planned according to standards, any damage will typically be recognised by the insurance company. “This is because, with consistent structural planning, proof has been provided that the system will last 25 years over its service life,” emphasises Cedrik Zapfe. “If the service life is shortened, there are two main reasons: Either mistakes were made in the planning or the corrosion protection was inadequate,” says the Schletter CTO.

Pay attention to corrosion protection

As with all steel structures, mounting systems made of steel require protection against corrosion. The thickness and quality of the anti-corrosion coating are critical factors in ensuring durability. Special corrosivity maps indicate the required thickness of the coating—typically a galvanised layer—based on the region where the system is installed.

For instance, steel components require a thicker anti-corrosion coating if the system is installed in coastal areas or industrial regions compared to installations in purely residential areas or open fields. In the first part of our series, we explored the effects of extreme weather on ground-mounted solar installations. In the second part, we will explain how to prevent damage. (su)