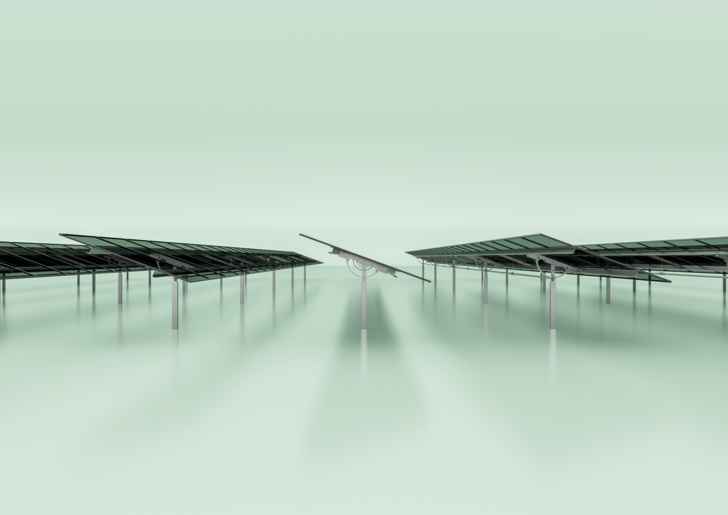

With the Tracking System 1P, the Schletter Group has made a great leap forward. The system is specially optimized for use with large format modules in portrait orientation. This means that even bifacial modules with a height of up to 8.2 ft (250 cm) can easily be mounted. The compact Tracking System 1P weighs less than 66 lbs (30 kg) per kW, which is approximately 30 percent lighter than comparable products on the market.

The Tracking System 1P has the same design advantages as the Schletter Tracking System 2P. The heart of the system is the patented mechanical self-locking Geneva drive: this gear system is used to rotate the arch at each post so that the structure is locked in place at any tilt angle, giving it the structural characteristics of a fixed tilt system. This eliminates wind-induced vibrations that can lead to resonance (also known as the galloping effect) without the need for dampers or other auxiliary solutions. The Schletter Tracking System in the stowed position can withstand wind speeds of up to 160 mph (~257 km/h).

FS Uno and PVMax: more yield, easier installation

Schletter Group

The Schletter Group will also present its ground-mounted systems in Las Vegas. These include the latest generation FS Uno single-post system. Compared to the previous version, the system requires less material per kilowatt of power - and it has a higher load capacity. This is made possible by using girders and purlins made of high-performance steel, as well as a new purlin geometry. The profile of the purlins is now an open-bottom isosceles trapezoid instead of a Z-shape. As a result, the purlins have a much higher load-bearing capacity, allowing spans of up to 19.6 ft (6.5 m).

The engineers have also fundamentally optimized and coordinated the system's individual components. For example, clamps are used for most connections, eliminating the need for drilling holes or time-consuming pre-punching. As a result, the system can be flexibly adapted to uneven surfaces, different terrain profiles and foundations.

See also: Schletter continues to grow in Q1 of 2023

The PVMax S ground-mounted system is also designed for fast and cost-effective project planning. The two-post steel system with a concrete foundation is particularly suitable for areas where pile driving is uneconomical or not feasible due to corrosive soil conditions. “For smaller PV systems, special soil surveys or pull tests are out of proportion to the total investment,” explains Cedrik Zapfe, CTO of Schletter. "The PVMax S scores with its cost-effectiveness and simple design, which also allows for quick installation with little effort."

FixGrid Pro’s aerodynamics reduce the required ballast

Schletter Group

In addition, the Schletter Group will present its newly enhanced flat roof system, FixGrid Pro. With the help of wind tunnel tests and improved aerodynamics, the ballast has been reduced even further. "Our wind tunnel tests have shown that it is aerodynamically much more advantageous to place the maintenance aisle between the upper edges of the elevated modules and not, as before, at the lower edges," emphasizes Dr. Zapfe. "In this way, up to ten percent of the ballast can be saved. This allows developers to maintain the necessary static reserves, even if the roof has limited residual load-bearing capacity."

Also interesting: Schletter on video: New mounting system for optimal use of space

Schletter’s developers have further improved the system according to the modular principle. Instead of using different module supports according to the tilt angle, module size, or orientation (portrait or landscape), all variants can now be realized with just a few universal components. This makes system design and installation much faster and more flexible. In addition, an optimal support and clamping position for the module is always guaranteed, regardless of angle and size.

Metaverse for solar innovations

Schletter Group

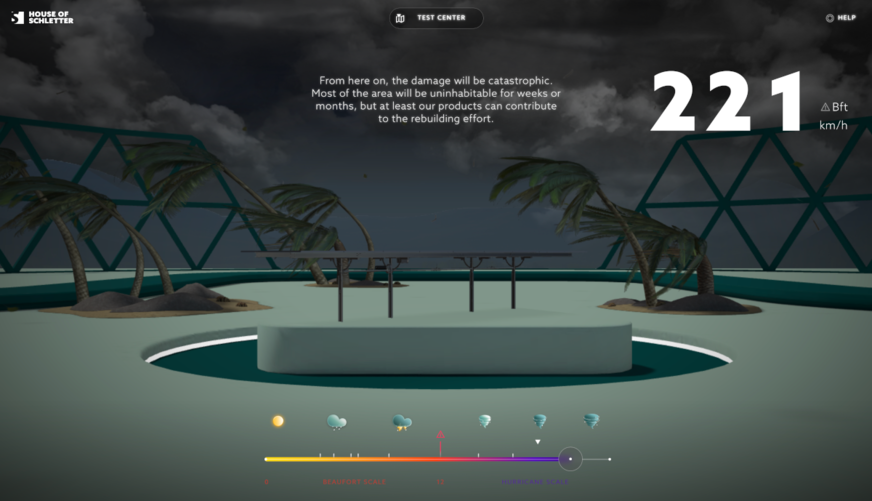

Furthermore, the company will present the virtual House of Schletter at RE+. Visitors to the stand can immerse themselves in the product world in a three-dimensional virtual space, also known as the Metaverse, and experience various applications and test scenarios. In the future, the Schetter Metaverse will be available to customers as a digital experience space independent of trade shows - additional experience spaces will be successively activated throughout the year. "We rely heavily on personal contact in sales and customer support, but on-site appointments or live demos are not always logistically easy," says Schletter Group CEO Florian Roos. "With the Schletter Metaverse, we can make our products and their technical details vivid and tangible anytime, anywhere in the world."

If you are in North America, you be able to visit the Schletter Group at RE+ in Las Vegas from 12 to 14 September 2023 at booth 21070 on Sands Level 1. (mfo)