Austria has set itself ambitious climate targets. In particular, photovoltaics is to be massively expanded. To meet the requirements with typical small-scale installations for single family homes with an output of five kilowatts, around 750 systems would have to be constructed - every day until 2030. However, there’s no need to worry about running out of roof space at some stage. Because in Austria, the trend is towards large installations with an output of several megawatts.

Largest solar park in Austria opened in November 2020

Austria`s largest outdoor photovoltaic system was opened in November 2020 in Schönkirchen-Reyersdorf, north east of Vienna. The 34,600 modules cover an area of 13.3 hectares, which is approximately 18 football fields. They combine to generate 11.5 megawatts, a total of almost 11 gigawatt hours of electrical energy per year, corresponding to the consumption of 3,400 households. This saves 8,000 tons of carbon dioxide per year. The next stage of the project will be a further 10,400 modules providing 3.5 megawatts and supplying 1,000 more households with green energy. The costs are split equally between energy companies OMV and Verbund, with KPV Solar having overall responsibility for constructing the installation.

Logistics matters: To the nearest hour

Lapp is also benefiting from the boom in photovoltaics in Austria, where the market is currently growing by 50 percent every year. The global market leader for integrated cable and connection technology solutions is one of the leading suppliers for photovoltaics in Austria and is seeing strong growth in sales. “Brands such as Ölflex are very well known here and are in high demand”, says Andreas Felber, sales engineer and the person responsible for photovoltaics at Lapp Austria.

A major advantage for Lapp is the superior logistics for which the company is known in many industries. Particularly in its project business involving wind parks and large photovoltaic systems, customers place great importance on precise delivery. In the case of the project in Schönkirchen-Reyersdorf, KPV Solar created a quantity structure as part of their planning as a basis for its orders from Lapp.

Lapp ensures that the specified goods are in stock at Lapp Austria in Linz, and the customer can then call them off as required. KPV Solar always gives a week’s notice of the day on which they need the goods and Lapp delivers them to the site on that exact day. Just-in-time delivery is a part of everyday life for Lapp these days. For wind farms, the requirements are even stricter; in some cases, the goods have to arrive on the construction site at exactly the right hour of the day.

180 kilometres of Ölflex solar cables

The heaviest cable drum that Lapp delivers to Schönkirchen-Reyersdorf weighs 5.5 tons. A crane has to be on hand to unload it and that costs money, with every delay pushing up costs. Felber is keen to reassure customers that Lapp does whatever it can to make their work easier. As a matter of principle, Lapp does not use hire drums that the customer has to pay rent for. Instead, Lapp picks up the empty cable drums free of charge and recycles them.

Lapp

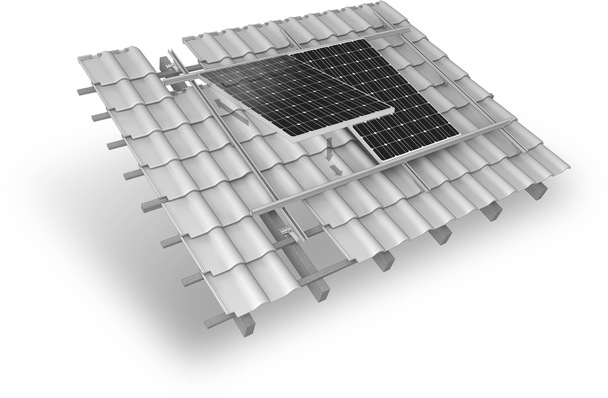

For such a large open air installation, a large number of drums come together. 180 kilometres of Ölflex solar cables have been installed in the DC section of the photovoltaic modules alone. The drums weighing several tons mentioned previously contain aluminium power cables that deliver the electricity from the inverter to the network operator’s transformer. Etherline Cat.7 data cables are also installed, and monitor the function and output of the inverters.

And then there are numerous accessories such as cable ties and Fleximark labels. Lapp also offers special Epic Solar connectors and Skintop cable glands for photovoltaic units. All components can withstand heat, frost, ozone and UV radiation, while the cables are flame retardant and halogen-free. And they are UL-certified, meaning that they can be used directly in the North American market.

Ready-made cables on trend

To ensure that these major projects really pay off in the end despite their tight costings, the connection systems need to last as long as the solar modules, which means 40 years where possible, as that’s how long the installation in Schönkirchen-Reyersdorf is intended to supply power for. Lapp connection systems are exceptionally robust and durable, making them the first choice in the solar industry. There is an increasing demand for Ölflex Connect - “it’s currently a hot topic in sales”, says Felber. Under this brand name, Lapp supplies a wide range of pre-assembled cables.

As the exact module widths and installation distances in an open air installation are known, the constructors tend to order the cables for the DC side pre-assembled, with the correct length and connectors already fitted. The technicians only have to plug in and secure the cables. There is no need to laboriously strip each individual cable and attach the connector in the rain and wind. This saves time and eliminates defects that cannot be completely ruled out with manual assembly on the construction site.

Further planned projects

For Lapp Austria, the largest photovoltaic park in Austria is an important reference project, with more to follow. OMV and Verbund have announced that they are already planning further systems, and there is also international interest. There are also plans to move into production of green hydrogen.

Did you miss that? Georg Stawowy of Lapp Holding AG: All Electric Society needs 100 per cent renewable electricity

It is likely that Lapp will be involved in these projects too, as the company is now so well connected. Lapp is a member of the Photovoltaic-Austria interest group, and Andreas Felber also regularly provides training for electrical planners and end customers and teachers at the technical college in Graz. “I'm always close to our customers and find out first hand what they need.” (hcn)

Read more: Lapp expands business in South Africa