The industry-oriented production line will manufacture a total of 4,000 roof tiles using matrix shingle technology. Since March 2025, 800 shingle modules have already been produced. Freesuns is currently installing five roof systems in existing buildings in Switzerland.

‘By manufacturing the first Freesuns matrix shingle roof tiles in the Fraunhofer ISE's Module-TEC, we can work together on production development and demonstrate the major advantage of matrix technology,’ explains John Morello, founder and CTO of Freesuns. The project is funded by the European Union.

Option for listed buildings

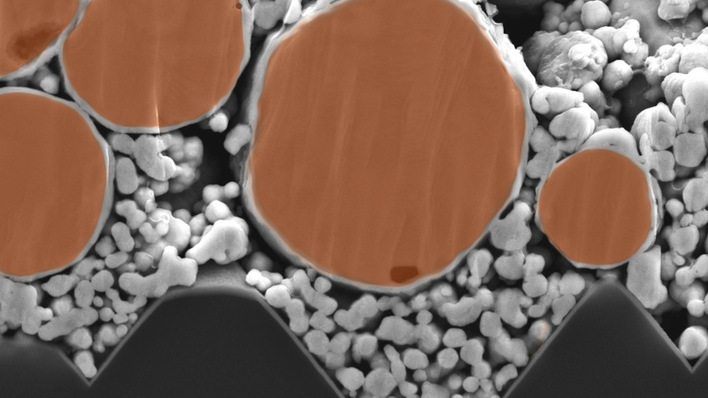

In shingle technology, solar cell strips are connected into strings using electrically conductive, lead-free adhesives. The cells are then layered in an overlapping pattern in the manner of traditional roof shingles.

Belgium: SolarMarket leads the way for urban PV

The modules manufactured in this way work more efficiently because the currents of the cell strips are smaller than in half-cell modules. The busbars of the solar cells are covered with active cell surface and there are no gaps between the solar cells of a string.

Roof integration: photovoltaics replaces tiles

The 450 x 510 mm solar roof tile consists of a glass-glass module with Topcon solar cells connected in a shingle matrix. Various colour options are available. ‘Our focus in this product development is on applications for existing buildings, especially listed buildings,’ adds John Morello.

High tolerance to partial shading

The shingled solar cells are also arranged in a staggered pattern. This enables complete, homogeneous coverage of the entire module area. The matrix shingle modules are four percentage points more efficient overall than conventional half-cell modules with wire interconnection. This is because shingle technology is characterised by a high tolerance to partial shading. The matrix arrangement allows the electricity to flow around the shaded areas, generating twice the power of conventionally wired modules. (nhp/hcn)