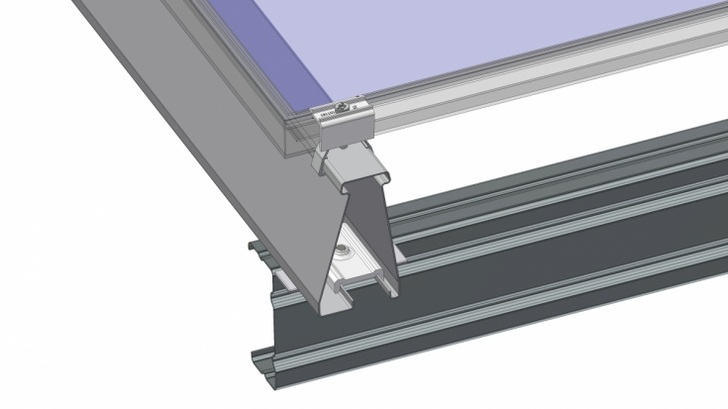

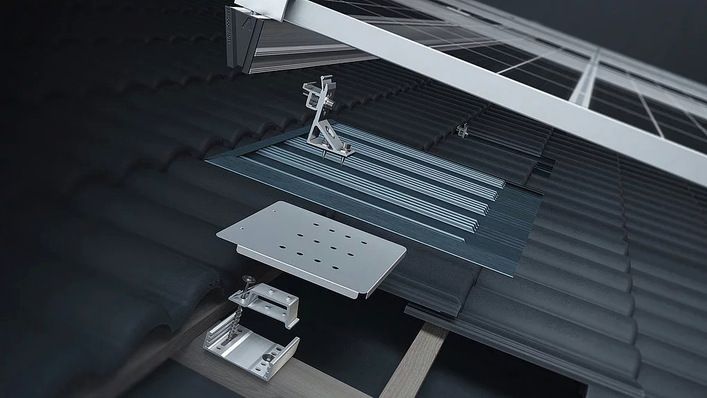

For the ramming foundations, binders and purlins of the FS Gen 3, Schletter uses a steel that is usually used in the automotive and mechanical engineering industry. At the same time, the geometry of the purlins was fundamentally redesigned: Instead of a Z-profile, the cross-section of the purlins resembles an isosceles trapezoid open at the bottom.

Had you heard about the Schletter Group's new US headquarters?

Combined with the new material, the new shape gives the purlins a significantly higher load-bearing capacity. Spans of up to 6.50 metres are now possible, some 20 per cent more than with the previous generation. This means that the FS Gen 3 can install more output with fewer supports.

The new geometry enables the purlins to perform another function in the future: they also serve as cable ducts. The string cables are routed in the purlins where they are protected from wind and weather as well as UV radiation. This eliminates the need for cable ties. (mfo)