This week's topic is commercial storage:

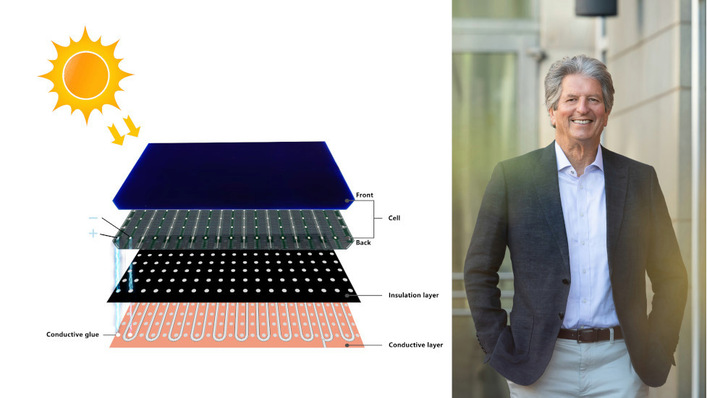

Mounted on a floating platform, lithium batteries with a total storage capacity of 158 kilowatt hours (kWh) have brought the diesel generators’ operating time down from 24 hours each day to just three. In raising a generation of salmon — a process which takes about 18 months — the company saves between 150,000 and 200,000 euros and also reduces its carbon footprint. German commercial storage system manufacturer Tesvolt worked together with Norwegian partner company Kverneland Energi to custom develop, deliver and install the battery system in accordance with the fish farm’s requirements.

Storage system cuts diesel use in half

Kvarøy, a third-generation family-run company, has taken it upon itself to run its fish farm sustainably. A major factor in implementing this policy was reducing the high rates of diesel consumption for operating the fish farm and the feeding systems. Two large diesel generators and one small one are in operation on the anchored concrete platforms. At least one of them must always be running since there is no power connection onboard. At the same time, the electricity demand fluctuates greatly within the course of a day — at feeding times, the systems require a lot of energy, whereas at other times, only the light on the approximately 20 m by 20 m large motorless ship is shining. Due to long operating periods and poor diesel combustion in the generators, each kilowatt hour of electricity brought with it considerable costs. Additionally, a large portion of the diesel was only used to keep the engine warm while a small portion actually drove the system. On top of that, the fuel has to be transported by boat to the salmon farm, which of course means additional energy and incurred costs.

Kvarøy salmon farm off the island of Selsøyvær in the Norwegian Sea.

For this unusual operating location, Tesvolt and Kverneland Energi came up with a special battery system solution. With its 120 kW peak power capacity, the battery system can be monitored and controlled from land over the internet. Power electronics from Siemens control all energy flows on the working platform fully autonomously and deliver electricity to all consuming elements. A diesel generator creates electricity for the batteries at full capacity operation and the electrical energy consumers are supplied by the batteries with the necessary electricity. The generator is not switched on and the batteries are not recharged until the state of charge is low. The battery system allows for a reduction in the fish farm’s total diesel consumption of up to 60 percent.

158 kWh Tesvolt storage system on the floating salmon farm.

“Tesvolt battery storage systems are the only ones on the market that can be fully charged and discharged twice in one day and still maintain their long service life,” Jonas A. Kverneland, Technical Director of Kverneland Energi, reports on his market research. “Many suppliers only enable one storage system charge and discharge cycle per day, which wouldn’t have worked for the salmon farm.”

Monthly oil changes reduced to twice a year

Helping to cut costs, the Kvarøy team now only needs to change the diesel generators’ oil biannually instead of each month. An oil change takes an entire day and costs up to 1,000 euros. That means that the company now saves ten working days and 10,000 euros each year in oil changes alone.

“The starkly decreased consumption of diesel contributes to climate conservation and keeps water pollution as low as possible,” Kverneland says — a key concern of the government in Norway. And one of the managing directors of Kvarøy and Kverneland customer Gjermund Olsen is equally pleased, stating, “We purchased, installed and forgot about the rechargeable battery. It runs on its own and is totally maintenance-free.”

Less noise and fewer emissions

His employees, who visit the platform to conduct maintenance work once a week on average, don’t even have to perform additional work thanks to the new energy system. On the contrary: they benefit from improved working conditions. Since the diesel generators are only rarely in operation, noise levels and vibration effects are lowered and the fish farm produces fewer emissions. (HCN)

Here, in case you missed it, is Part 1 of last week's series.