This collaboration was showcased during the opening event of Solarge’s new production facility in Weert in the Netherlands on 22 May 2023. Representatives from Sabic and Solarge attended the ceremony, along with other industry and political leaders.

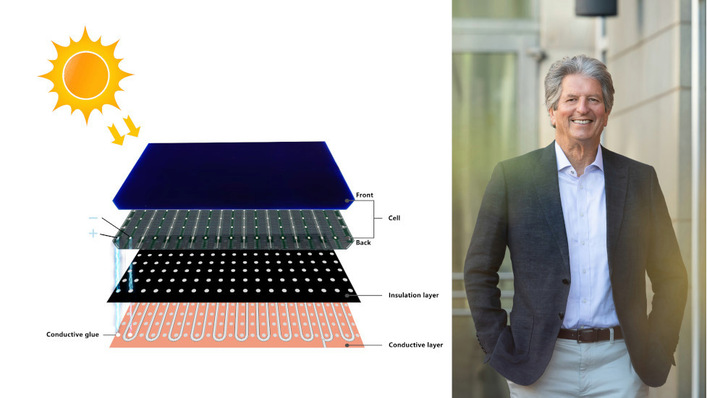

Sabic worked closely with Solarge to develop a low carbon footprint solar panel made from Sabic PP (polypropylene) compounds. Today, many building roofs cannot sustain the weight of the current glass PV panels, but Sabic PP compounds used in these solar panels provide more than 50% weight reduction.

See also: Energy consumption in IT - on the way to net zero

In addition, PV panels made with this material result in more than 25% carbon footprint reduction and can be reused within their own production chain after 25 years. These features attract a high demand for application on industrial roofs as customers in the commercial and industrial building segment seek lighter and more energy efficient alternatives.

Some such PV panels have already been installed

The initial concept for the lightweight, circular PV panels was developed and patented by Sabic and Solarge. In this unique collaboration, Sabic developed differentiated polypropylene materials to enable the Solarge lightweight solar panel to meet performance requirements. Sabic then worked together with Solarge in the further application, development and testing of the concept, installation, and supported the industrial scale up of the product for market entry.

Also interesting: Market of re-used PV modules around 500 to 600 MW yearly

The Sabic PP compounds used in these panels will be produced at Sabic’s polypropylene compounding site in Genk, Belgium. As the next step, Sabic has already installed 50 of these lightweight PV panels on the roof of this manufacturing facility in a pilot project, marking the start of a full-scale roof installation of nearly 5,000 panels during 2023. This also reaffirms Sabic’s commitment to drive the energy transition toward renewable power through both material applications and reducing the manufacturing carbon footprint. (mfo)