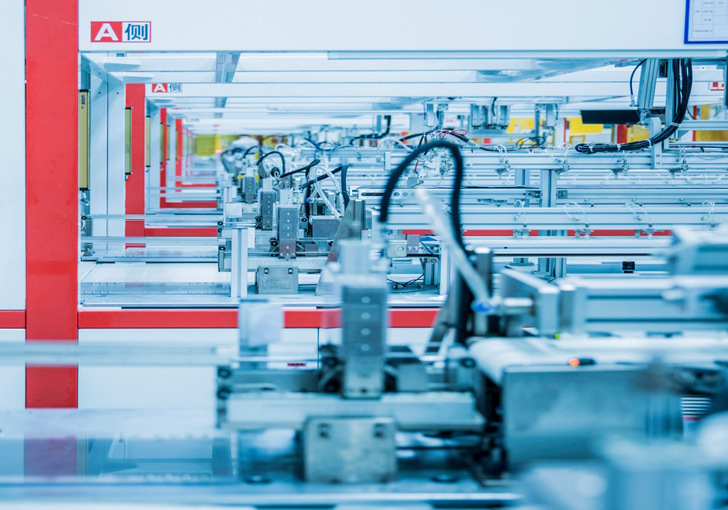

As Longi is one of the 21 new Lighthouses globally, the WEF made the following remark about Longi's manufacturing competitiveness: “Empowered by a number of intelligent technologies, Longi’s Jiaxing Production Base has developed and implemented more than 30 digital technologies to promote intelligent manufacturing, many of which are industry-first independent patented technologies, reducing unit manufacturing costs by 28% within one year and reducing yield loss. It is reduced by 43%, the production delivery cycle is reduced by 84%, and the unit energy consumption is reduced by 20%. ”

The essence of the Global Lighthouse Factory is a digital transformation of production. The core is the strategic capability of building an intelligent manufacturing system. Through the extensive application of digital technologies such as Automation, Industrial Internet of Things (IIoT), Big Data Analysis, 5G, etc., it can improve resource demand, planning management, and flexible production, logistics transportation, customer service and other full value chain systems for lean management.

Flexible automation enabled by artificial intelligence and machine vision

By optimizing processes and supplier collaboration, combined with visual AI positioning and other technologies, Longi Jiaxing Production Base overcomes 7 photovoltaic module industry automation problems, such as lamination and assembly processes, making the whole line process stable and best in the industry.

AI-powered full-process visual inspection, precise traceability, root causes and action recommendations

Longi Jiaxing Production Base achieves full coverage of 20 processes, and deploys a total of 784 cameras, collecting tens of thousands of point data. The AI-powered process can display abnormal change trends and yield change trends of the covered processes in real time to assist decision-makers in making quick decisions. It can analyze the causes of various types of hidden cracks and welding defects, and recommend the best solution combined with expert knowledge system to quickly deal with anomalies.

Also interesting: New silicon solar cell efficiency record

In addition, the AI-powered process can accurately identify 1,000+ image features on the cell string, and through feature similarity calculation, complete the source machine information identification of 12 strings of cells every 18 seconds, replacing the original virtual code traceability.

Intelligent management of order production delivery cycle

Longi Jiaxing Production Base introduced 20+ digital sub-use cases along the production, warehousing and logistics value chain, reconstruct the end-to-end business process, greatly improve the efficiency of warehousing and logistics, achieve full traceability of logistics links and shorten the order cycle, ensure on-time delivery, and improve customer satisfaction.

AI-powered solar cells resource matching and dynamic correction

Longi Jiaxing Production Base deployed the industry's first self-developed AI smart solar cell production plan calculation system to calculate the optimal production plan to achieve accurate module power delivery and reduce power loss to meet customer needs. Longi believes that accurate delivery of module power is of great significance to cost control. After the better allocation of each efficiency cell sheet in AI intelligence, the module power that meets the needs of customers is produced, reducing power waste and cell cost.

Did you miss that? 700 W+ PV Open Innovation Ecological Alliance launched

“Innovation is the core competitiveness of enterprises and the inexhaustible driving force for their sustainable development. In the photovoltaic industry, technological innovation ability is particularly important,” said Zhong Baoshen, Chairman of Longi. “It is necessary to speed up the intelligentization and digitization of the company through The Global Lighthouse Network initiated by WEF, which are important for the transformation and upgrading of the photovoltaic manufacturing industry in general.” (hcn)