Perovskite-silicon tandem cells may be drawing attention across the PV industry with lab-scale efficiencies above 33 percent, but scaling up production remains a challenge. Recently, researchers at KAUST and Fraunhofer ISE succeeded in replacing spin-coating with blade-coating in the fabrication process – a key step toward industrial manufacturing of this high-potential technology.

Researchers from Saudi Arabia and Germany have reported a promising breakthrough. Using a hybrid route that combines evaporation and blade-coating to deposit perovskite layers on silicon bottom cells, they achieved tandem solar cell efficiencies approaching 28 per cent.

Expert analysis – how perovskite can overcome durability concerns

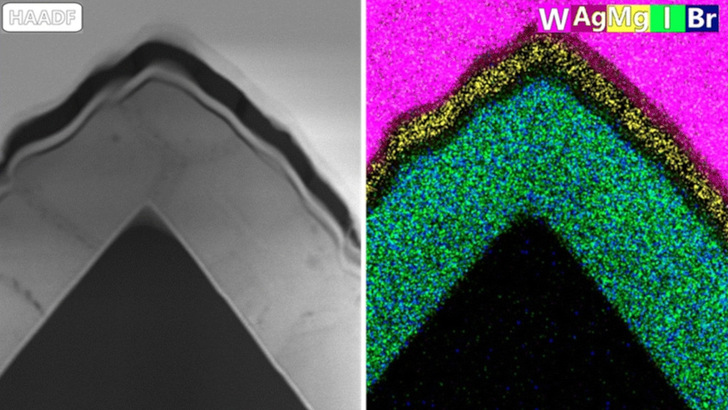

“Successfully applying the perovskite materials with scalable technologies on the silicon bottom cell has been a break-through for us”, said Oussama Er-raji, doctoral student and project lead at Fraunhofer ISE. “An a two-step hybrid process, the inorganic components of the perovskite absorber are first evaporated, followed by the blade-coating of the organic components. This makes it suitable for a production on an industrial scale.”

Coating speed does not affect perovskite thickness

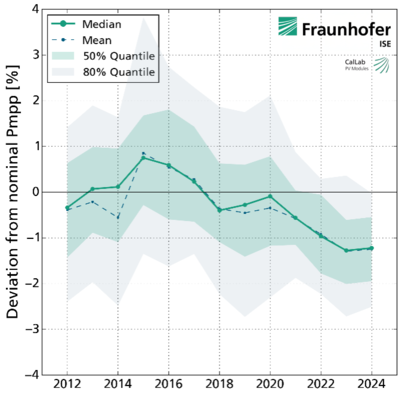

The scientists demonstrated fully textured perovskite–silicon tandem solar cells with open-circuit voltages exceeding 1,900 millivolts and efficiencies of 27.8 per cent. They also found that, unlike in one-step blade-coated perovskites, the coating speed in the hybrid evaporation/blade-coating process does not affect perovskite thickness but correlates with the perovskite conversion rate – a key factor in optimising the absorber.

Stay tuned – subscribe to our newsletters

With this study, the Fraunhofer ISE researchers built on their extensive experience with the hybrid route, which combines evaporation with a wet-chemical process step. While spin-coating had previously been used for the wet-chemical step, they have now transferred their expertise to the more scalable blade-coating method for the second step.

Tandem solar cells in vogue

Many perovskite research groups, including KAUST and Fraunhofer ISE, are investigating pathways to enable the mass production of perovskite–silicon tandem solar cells. So far, these cells have mostly been produced using spin-coating.

The smarter E – perovskites a long time coming

“Spin-coating is great as a lab technique as it is very flexible and allows for rapid testing of new materials, additives and process parameters. For large scale production it is however not suitable”, said Dr. Juliane Borchert, group lead on Perovskite Materials and Interfaces at Fraunhofer ISE. “We also expect that the learnings about the dynamics during blade-coating can be transferred to slot-die-coating which is even more suitable for scaling”, Borchert added.

Perovskite – Oxford PV and Trinasolar sign patent agreement

Silicon solar cells can convert a theoretical maximum of 29.4 per cent of sunlight into electricity. To further improve solar cell efficiency, researchers worldwide are turning to tandem photovoltaics – especially the combination of a silicon bottom cell and a perovskite top cell. While the silicon sub-cell converts the red portion of sunlight efficiently, a perovskite top cell can better utilise the blue fraction of light. (hcn)