A flurry of announcements over the past three years has seen the factory pipeline swell to levels that put the industry on track to satisfy demand over the next five years. Maintaining this momentum will be crucial for the surge in green hydrogen to follow thereafter.

In 2020, the global production capacity for electrolyzers was just 2 gigawatts, sitting substantially higher than the world’s total installed capacity of 300 megawatts. This was at a time when the conversation around hydrogen was dominated by doubt. But now, things have changed.

Green hydrogen for decarbonising industries

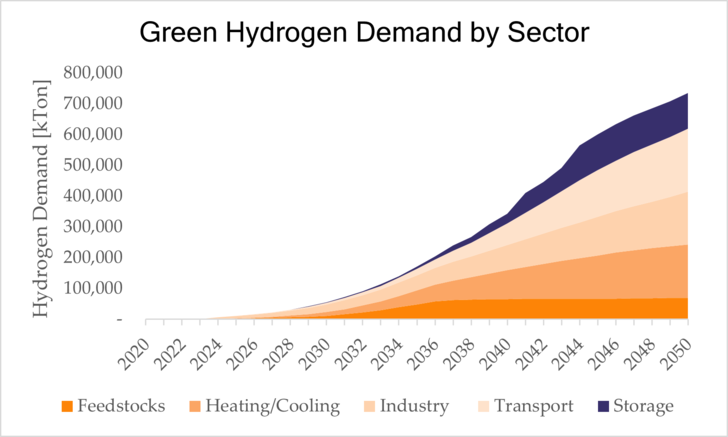

Hydrogen has been identified as a key technology for the decarbonization of heavy transport, heating, industry, feedstocks, and long-duration energy storage. Rethink Energy’s latest report anticipates that by 2050, global hydrogen demand will have grown ten-fold to 735 million tons, with almost all of this being produced using electrolysis.

See also: DLR solar tower: Synhelion produces solar synthesis gas

And nearly 40 gigawatts of electrolyzers are set to be installed in the next five years alone. Great efforts will have to be undertaken to build enough factories to support such growth – but the market leaders are ready. As are a handful of new-entry innovators.

42 gigawatts per year by 2030

ITM Power completed the world’s first electrolyzer Gigafactory in January 2021 in the UK, and announcements have snowballed since. Over the past two years, western electrolyzer manufacturers have committed to building factories that can produce over 42 gigawatts of electrolyzers per year by 2030. In total, around 6 billion US dollars will have to be invested in the construction of these new factories.

Fourteen different manufacturers, across twelve different countries, now have plans for an electrolyzer Gigafactory. There will be space for different chemistries – PEM, AEM and SOE to name a few – as the specific requirements for electrolysis plants varies from site to site.

Green hydrogen to be cheaper than grey hydrogen

Such Gigafactories will be crucial in reaching the much-needed economies of scale for green hydrogen. By 2024, several OEMs will be providing systems than can produce green hydrogen at a lower cost than ‘grey’ hydrogen, i.e. produced using natural gas.

The ability to produce small-scale, modular electrolysis cells, at scale, will make hydrogen accessible for swathes of industries that need it to decarbonize. Rethink Energy predicts that even without any sudden improvements in technology – of which several are almost certain – the capital cost of electrolyzer units can fall from around 1,400 to 340 US dollars per kilowatt by 2030, as global capacity rises to nearly 100 gigawatts.

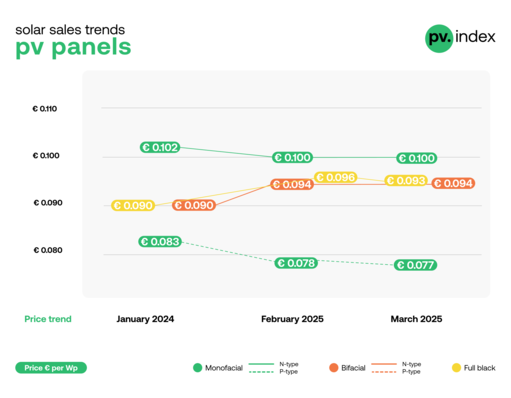

Demand and price of electricity expected to fall

Incremental improvements in efficiency and capacity factor will also see a reduced demand for electricity, which itself will be falling in price. With similar economies of scale, the cost of solar power in particular will fall below 20 US dollars per megawatt hour by the end of the decade, accounting for 37 per cent of the overall cost reduction of green hydrogen. By 2030, the global average cost of green hydrogen will have fallen to 1,50 US dollars per kilogram. (mfo)