Solargik has developed a very slim system for agri-PV and difficult areas. How is the system constructed?

Gil Kroyzer: Solargik’s systems are designed with the shortest tracker table on the market that ranges in length from 8 to 24 panels. This modularity enables adaptability across different terrains, including sloped or irregular landscapes or dual-use projects. The structure incorporates tilted bearings, vertical pylons, and enhanced wind load protection to ensure stability and optimal performance in various environmental conditions.

In which scope is the height of the system adjustable?

The height of Solargik’s systems is variable depending on project requirements, such as agricultural activities beneath the panels or terrain constraints. For agrivoltaic projects, for instance, the height is adjusted to allow sufficient space for crops and agricultural machinery, supporting dual-use applications. Solargik has installed trackers at heights up to 5 meters.

How is the mounting structure anchored?

Solargik’s mounting structures are anchored using vertical pylons designed for stability, even on challenging terrains. These pylons, paired with additional cabling for reinforcement, withstand multi-directional wind loads and slope stresses, eliminating the need for extensive grading or cut-and-fill earthwork. In agrivoltaics the foundations are often adapted to the constraints of the specific agricultural use.

What is the distance between the mounting posts to enable the farmers to use the land for working with agricultural machinery?

The distance between mounting posts is customised based on the type of agricultural machinery and crop being used. For example, in one of our projects in the Jordan Valley agrivoltaic project, the spacing supports access for farming equipment while ensuring efficient energy production and crop growth.

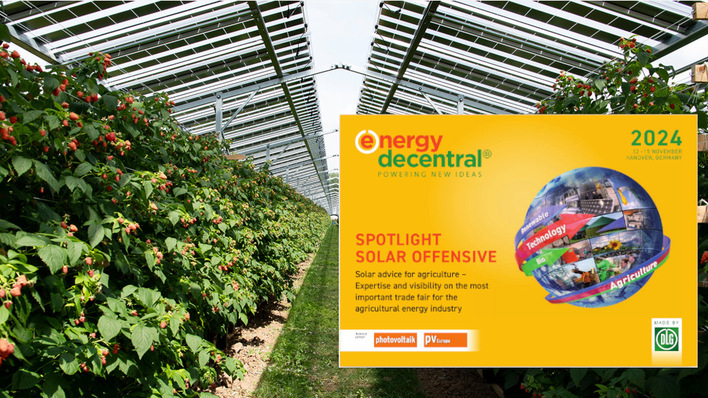

PV from field and barn: Our special for the dual harvest on farms

The high elevation of the systems appears to be suitable for vineyards and greenhouses. Are there also options for arable farming?

Our solutions are adaptable to a wide range of agricultural uses, including vineyards, greenhouses and arable farming. The modular design and tracking algorithms are tailored to balance light requirements for crops and energy generation, making it suitable for diverse applications. We have projects globally over tomatoes, lychee, avocado, grape vineyards, berries, and more.

The solar modules shade the area below. How much light can reach the plants with your system?

Solargik’s systems are designed with an optimal ground coverage ratio (GCR) of around 50 percent, allowing adequate sunlight to reach the plants below. The tracking algorithms adjust the tilt and orientation of the panels to maximise light for crops while optimising solar output.

Fraunhofer ISE: Lightweight modules developed for agrivoltaic systems

What plants do well in these conditions?

Solargik has experience with various crops, including grapes, mangoes and lychees, as demonstrated in the above-mentioned Jordan Valley project. These crops thrive under conditions where partial shading reduces heat stress and conserves water, enhancing agricultural yields.

Does the system include a way to collect rainwater and store it for watering?

While the primary focus of Solargik’s systems is on energy generation, projects could incorporate complementary rainwater collection systems to support agricultural irrigation. This is typically determined by project-specific requirements and local conditions.

New study highlights potential of UK agri-PV

Which modules do you use in your projects?

We are partners with leading PV module manufacturers to accommodate high-efficiency modules tailored to project needs. Solargik accommodates any type of module as per the requirements of the development partners we work with. Bifacial modules are often used in agrivoltaic setups to capture additional light reflected from the ground, increasing energy yield.

How are the trackers moved? Is it each row individually or is there a central motor that moves numerous rows?

Our trackers are designed to move each row individually. This row-level control maximises flexibility and ensures that trackers can adapt to the specific conditions of each section of the project site, especially on irregular terrains.

How are the systems planned and controlled to maximise both the yield from the land and of PV?

Solargik utilises advanced tracking algorithms and 3D modelling to harmonize agricultural and PV yields. By dynamically adjusting panel orientation based on solar and agricultural needs, the system ensures an optimal balance between crop growth and energy generation. For that, the trackers are controlled using advanced algorithms that incorporate real-time data from sensors. These sensors align the panels with the brightest point in the sky while considering factors like shading, terrain, and weather conditions to optimise performance. What makes Solargik’s approach unique is SOMA, our SCADA offering.

Agri-PV: “Dual use with animal husbandry has great potential”

What is so special about this approach?

This is an intelligent software solution that encompasses both tracker control and full site management. Unlike conventional tracking systems that operate based solely on pre-set movement patterns or light sensors, SOMA dynamically adjusts in response to site-specific conditions. This enables agronomists and farm operators to make precise, real-time decisions about shading adjustments and microclimate control, directly impacting crop yield. This holistic site management approach sets Solargik apart in the agrivoltaics space, enabling farmers and developers to fully maximise land use efficiency while ensuring long-term sustainability.

Interview by Sven Ullich.

Solargik will present its tracker system at The smarter E Europe at booth FN100/34 in the outdoor area of the trade fair next to hall C4 at the north entrance.