Peitz near Cottbus near the Eastern border of Germany is generally more of a quiet spot. This area along the eastern edge of Germany is usually better known for the Peitz Ponds, where carp are reared for New Year’s Eve. But we are more interested in the photovoltaics installation of Sven Minetzke. He deals in spare parts for HGVs. “In late 2011, I had a solar array installed to the roof of my warehouse,” he recounts. “Back then we installed 267 solar panels from S-Energy.” Installing the PV has helped him to refurbish his roof, formerly made of asbestos, with sheet metal and solar panels.

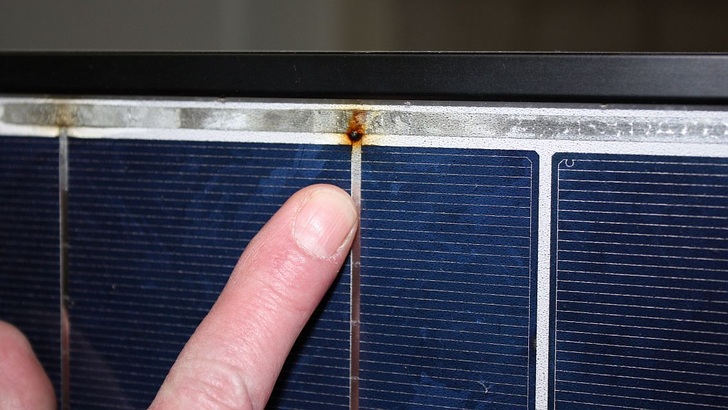

The panels were bought from Donauer, a distributor that has since gone insolvent. “Half of the panels are currently defective,” Minttzke complains. “In 2016 alone we lost about 6,000 euros.”

Textbook case for monitoring

Minetzke’s story is a textbook example why proper monitoring is important. “At first, all seemed to be going well,” he remembers. “The inverters were showing yields, there were no failures.” Four Sunny Boy Tripower 18,000 and three 15,000 combine the strings and feed the AC power into the regional grid. “When I accounted for the yearly values at the end of 2015 I realised that yields were going down.”

At the beginning of 2016, technician installed a Solarlog 1,000 in order to systematically monitor the system. The firmware of the data logger was updated in February 2016. Since then, the Solarlog can access the reference values of similar installations in the area which are also being managed by a data logger. “That took me by complete surprise,” Minetzke says. “We saw a deviation of minus 25 percent. We then subjected the the installation to a thorough inspection.” (Heiko Schwarzburger)