How long has Suncycle been active as a service provider in the solar industry?

Mischa Paterna: Our first project was an installation by Tauber Solar in Bürstadt in 2008. At 5.5 megawatts, this was the world's largest on-roof array at that time. The panels were supplied by BP Solar. Because parts of the installation caught fire due to a technical fault, there was even a risk of injury and death at the time. Later we have worked a lot for large companies such as Schüco, Schott and Bosch, whose excursions into photovoltaics were unfortunately all terminated.

What is your role today?

Today we see ourselves as a provider of a wide range of after-sales services and repairs. The systems are becoming more complex. Starting point is the data from the operational monitoring of the installations in order to find the causes of faults resulting in lower yields. We take measures to evaluate the defects, and replace or repair components. To make such decisions, you need to have extensive experience in the field so that interventions can be properly budgeted.

Which markets is Suncycle involved in?

In the European Union in particular, especially in Germany. And since 2015 also in the US.

What are you not offering, which, however, is occasionally expected of you?

We have never been involved in the design and construction of new installations. We have only ever done rebuilding work. And we do not certify solar panels, for example, as provided by the TÜV and their laboratories.

Who are Suncycle's customers?

They often come from within the industry, primarily manufacturers. In addition to panel manufacturers, producers of inverters and, most recently, storage manufacturers are also looking for smoothly functioning services. Sometimes it is the operators of an installation. Installing companies and insurers also play a role. Customers often expect us to offer an all-round carefree package at a flat rate. We are doing our best to ensure that such models will one day find their way into the industry.

How difficult is a customer such as S-Energy?

We were commissioned by the Korean panel manufacturer S-Energy to handle the warranty in Europe. Customers with complaints about S-Energy panels believe that we also dispose of the budget and have decision-making authority. But we can only move within the narrow boundaries set by S-Energy. We are in difficult negotiations with the Koreans to increase the necessary budgets and capacities. At last, in early 2018, larger volumes of panels and budgets are to be made available in order to handle the complaints, some of which have been known for quite some time.

What is the average size of the installations you manage?

From the very small to the very large. For private customers, it is sometimes a matter of replacing plugs on the roof. You might have to pull up 15 panels. However, you need scaffolding, two mechanics have to come out. That can be quite expensive. A working day like this can quickly add up to 2,500 euros. You have to consider that carefully. For larger installations, we usually act on behalf of the manufacturer or operator, as well as also carrying out maintenance work under O&M contracts.

You began almost a decade ago. Looking back, is it fair to say that fewer faults are occurring? That the quality of installations has improved?

The number of defects has not actually declined. Although experience in production has expanded, cost pressure has also increased. For example, we do not yet understand how PERC cells degrade and what will happen in that area. In my view, we are not out of the woods there. Delamination and issues with junction boxes are currently playing an increasing role in all major markets. Worth mentioning are also new technologies such as EL, which bring to light extended quality problems, or new fault patterns such as PID, which were never an issue 10 years ago.

How many employees does Suncycle have now?

We are 65 people, plus our service partners who support us on the ground. Our staff provides technical support for our industrial customers or works as specialist engineers to evaluate defective systems. The range of tasks and responsibilities we cover is very broad.

How is good service for you? How would you define that?

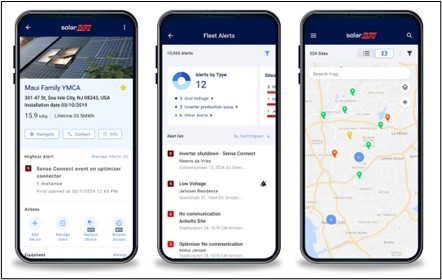

Good accessibility of the service provider, a clean preliminary calculation and accurate implementation within the agreed budgets are key. It is also important to stick to the agreed schedule for fixing a fault. Detailed documentation, for example using an inspection app, is also gaining in importance. The processes and calculations must be transparent and honest.

What is the significance of plant monitoring?

As I said at the beginning: It is the basis of good service. Ideally mapping operating data for each individual panel, as is the case with Tigo, Sunsniffer or Solaredge. In reality, many installations have no operational monitoring. This of course increases the time and effort involved in troubleshooting. This requires a lot of experience. Even if a monitoring system has been installed, this does not mean that it works correctly. Sometimes an installation indicates loss of yield, but the problem may only the data logger having crashed. Or that the SIM card is overloaded while the installation is properly connected to the grid.

Service is part of the value chain in photovoltaics and must be factored in before the investment. How can this work?

By first becoming aware of the importance of value preservation. In the UK, prices for plant maintenance are currently so low that nobody can do anything properly. Digitalised and effective procedures are crucial, in order to bring installations back up to their original yield as quickly as possible. This requires a digital record for the installation which supports the use of the installation with history and documentation in real time. The installing electrician's handwritten notes will not get you very far.

What solution do you offer for this?

During the inspection process, we use a specialised service app that allows the transfer of system data and the electronic documentation of on-site operations. Such optimisation of the procedures and the quality assurance this makes possible is immensely important for us. About 10 percent of our staff costs go into this. It is impossible to work efficiently otherwise.

The interview was conducted by Heiko Schwarzburger.

Stay informed, get our newsletter twice a week.

Register here: http://www.pveurope.eu/Newsletter

Also watch out for:

https://www.pveurope.eu/installation