Since Eon launched its PV plant check in 2015, more than 600 tests were carried out. All data obtained were anonymized and methodically uniformly recorded. On the basis of these data, Eon is now working with the Fraunhofer CSP project partners from Halle and the ZAE Bayern to develop a study that identifies the individual deficiencies in an aggregated form, thus enabling statements on particular frequencies and distributions.

Often wrong type of cables installed

It is already clear: frequent reasons for impairments are cables which are not laid correctly, sometimes even of the wrong type, which were neither suitable for outdoor use nor the occurring voltages. A fault with potential hazards that can be avoided.

Small and large-scale systems tested

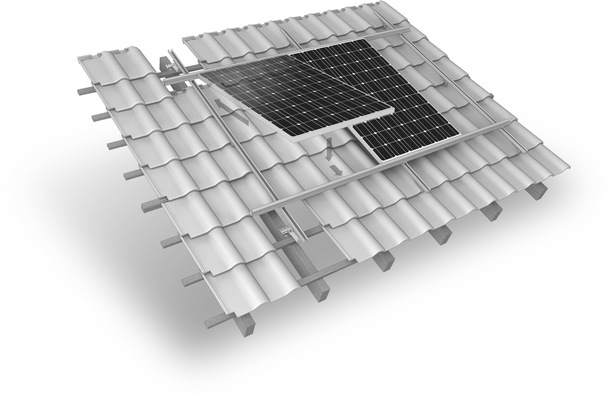

"Our experts were in use on hundreds of roofs throughout Germany over a period of one and a half years, and have tested smaller in a kilowatt range and large ground-mounted systems with up to five megawatts," explains Matthias Krieg, Head of Maintenance and Service at Eon Energie Deutschland. "We want to use the results for the targeted expansion of our maintenance offer. The data also help to identify approaches for further improvements in photovoltaics. "

Statements about regions, grades or types of modules

For the study, Eon provides the extensive results of its tests in an anonymous form as to the location and size of the plants, the commissioning, the electricity generated and the results obtained. This results in a representative cross-section, which on the one hand shows the proportion of installations in perfect condition, on the other hand also provides information on the extent to which safety-relevant abnormalities and losses in yield occur. It is also possible to determine whether specific regions, grades or types of modules are particularly affected by this.

Research partner Fraunhofer CSP

The Fraunhofer Center for Silicon Photovoltaic CSP has been supporting the energy supplier for a long time in the quality and reliability assessment of modules and plants. For the study, the research facility in Halle (Saale) assumes the characterization of modules, components and materials. "With our expertise and our research facilities, we can combine materials science analysis and mechanical tests at the module, as well as performance measurements in the laboratory and in the field as well as simulations for different stress factors," explains Sascha Dietrich, who is responsible for the project at Fraunhofer CSP. (PF/HCN)

Stay informed, get our weekly newsletter. Register here: http://www.pveurope.eu/Newsletter

Related news: