What are you focussing on when it comes to further developing energy storage batteries?

Hermann Schweizer: Using the software to integrate the community, the SonnenFlat and our new City model into the hardware has been most important to us. The issues revolve around controlling and managing the battery pool, but were also about sensors as well as gathering data and processing it within the storage unit.

Energy density or parameters such as the number of cycles, are they no longer important?

Of course, we continue to work on these, but such developments happen continuously. Our customers no longer focus so much on performance figures or the number of cycles as was the case just a few years ago. Today, people just assume, and rightly so, that storage units will last ten or more years.

Nevertheless, it would be quite advantageous if equipment became more compact...

Sure. The compactness of the units remains an important goal for our developers. You can see what strides have been made in six years if you look at the hulks we put on the market in 2011. These days, sonnenBatteries are quite manageable. Now, eight generations on, our product has shrunk significantly compared to the initial unit, while also performing much better.

How important is the effort involved in the installation?

The units need to become lighter and setting them up needs to keep getting easier. This is also true if you offer a number of services as we do. This is quite a challenge: Take our new City unit for people living in city flats. It has to be installed within the flat itself. Unlike in a house where the storage unit can be down in the basement next to the metre cabinet and where three-phase connections can almost be assumed. In a flat, there is much less scope for interfering with the existing power supply systems.

How are the units integrated?

We try to gather all of the important operational data via the battery itself, i.e. integrate them into the system. When connected to the building, the battery is managed by a sensor at the main metre. For the city model, this can usually only happen in newly built buildings where the owner and developer decides to set up all flats in this way from the get-go. In existing housing, it is usually impossible to get to the metres. So we record the consumption using special transformers at the junction to each flat. That also needs to be very simple: both to install and to operate. Our sonnenFlat box is connected via Powerline, thus communicating the operational and consumption data back to our headquarters, double-encrypted and as part of a completely independent communication system.

Are there security challenges that go along with that?

We have by-and-large adapted the protection profiles developed by the Federal Office for Information Security (BSI). Unfortunately, this process takes a long time to complete. And rolling out the smart metres is also bound up in such an issue. We are still not sure when we can start distributing the certified metres.

You are using round cells by Sony. Sony itself is up for sale. Will you continue with these cells or are you looking for alternatives?

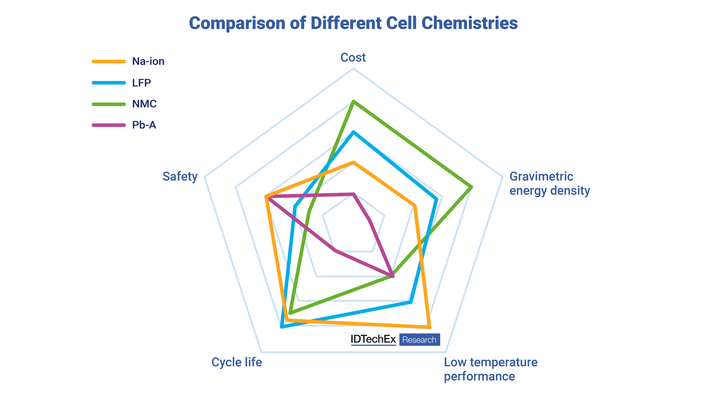

We are paying close attention to the battery market. We even have our own battery lab and specialists. After all, when looking at the alternative products that the market has to offer, and in order to really evaluate and assess them, we need to test them ourselves. This is about more than the technical parameters; it is about the quality of the storage cells. So far, Sony’s cell has been the best on the market, and is thus our cell of choice. Keep in mind: Sony have more than 25 years of experience in lithium cells. Generally speaking, the sonnenBatterie is not limited to a certain type of cell or a specific cell chemistry. This gives us the flexibility to always use the available technology that works best for us.

Your batteries run on 48 volts DC. Are you at all involved in high-voltage systems?

Yes, that is true, there is a general trend towards higher voltages. As part of the optimisation of our over all systems, we will also look at voltage. But we will certainly not go beyond 400 volts.

Why not?

Granted, higher voltages allow lower currents. And lower currents make it possible to reduce the costs of wiring and semi-conductors in the power electronics. But on the other hand, the costs on the battery side, such as balancing the cells or for components that need to be able to tolerate greater voltages, go up. What is needed here is a good compromise.

What it comes down to is price. Even your sector has seen some heavy competition. What future developments do you foresee?

Last year we saw price reductions, and that trend will continue in 2017. I think we will experience a very moderate lowering of prices over the year. We expect that because of our integrated services, will not have to worry so much about falling prices. Simply building the cheapest batteries that can store and give off electricity is not our goal. That is why we invest a lot of money into developing the software and into the platform for our integrated services. These things give our customers a clear and economic additional benefit.

The interview was conducted by Heiko Schwarzburger.

More useful information about energy storage systems:

Solar panels:

Choose your right solar panels

Electric cars:

Learn about electric cars to make more use of energy storage

Stay informed, get our free newsletter twice a week, register here