The domestic storage market has gathered pace, and now storage is also gaining a foothold in the commercial segment. What capacity marks the upper limit of domestic storage for private customers in your opinion?

Andreas Lipphardt: That is less a matter of size than of what degree of integration the customer wants. Is the battery just there as a buffer to increase self-consumption? Or is it also meant to even out load peaks in order to reduce the demand of additional power from the grid? Are electric vehicles involved?

Let us take the first case: simply a capacity buffer for self-consumption…

Andreas Lipphardt: Installing companies can usually put that sort of thing together on their own. Even up to capacities of 100 kilowatt hours or more. These kinds of solutions can be easily achieved by scaling up standard storage units. However, note that such scaled-up systems usually come in 20 or 40 kilowatt hours, with 100 kilowatt hours being a rare exception. For 20 kilowatt hours, you can combine two LG Resu 10s, whereas six IBC Solstore Li 6.5s add up to 40 kilowatt hours.

Are storage units generally getting larger?

Andreas Lipphardt: In the domestic segment, this is indeed what we are seeing: two or three IBC Solstores are usually combined. Here, the output required tends not to be all that high. However, customers are increasingly demanding for emergency power capability and overload resistance, and to that end they buy larger storage systems to have the necessary capacity reserves.

In domestic storage, it is common to combine standard systems. Is that also the modus operandi for commercial storage where the capacities and outputs are higher?

Uwe Schmidt: Larger units for commercial customers are always system solutions individually catered to the requirements of the company. Whether standard systems are suitable has to be determined in the planning phase. First of all, it is important to understand the customer’s needs and then to jointly work out an optimised storage solution.

Andreas Lipphardt: If possible, preference should be given to standardised systems for reasons of both flexibility and availability. These allow the installation of up to 200 or 300 kilowatt hours and 70 or 80 kilowatts charging or discharging capacity.

What sort of customers ask for commercial storage?

Uwe Schmidt: Most commercial customers not only ask for storage, but they are looking for a comprehensive solution to save energy, or to make more efficient use of it. Sometimes what they need is software to manage the complex energy flows, sometimes electric cars are involved. To respond to these kinds of demands, you either have the competencies within your company, or you find external partners to help you find the ideal solution. That is why this business segment requires more customer service than with standardised systems.

What motivations have priority?

Uwe Schmidt: For private customers, self-consumption usually has priority. In the commercial segment, the motivations are generally more diverse, as they make use of a wider range of functionalities of storage units. This can add to the complexity: In addition to self-consumption, it can be about peak-shaving or safeguarding the continuity of company processes. Furthermore, the market might ask us to provide back-up solutions.

Andreas Lipphardt: It can often be about harmonising a variety of systems within a company. Hardware and systems need to be able to communicate; that requires the appropriate interfaces and protocols. Getting that right can be quite tricky.

So, you have to invest a lot of time into planning even before you get the commission?

Uwe Schmidt: It is just as with any project-based commission in photovoltaics: Preliminary planning is gaining in importance for storage, in order to save money in the long run during the application. You have to answer the key questions on how the storage system is to be used, before you can formulate and suggest the appropriate solution. Once you get to the stage of installation and putting in operation, the customer’s requirements have to be programmed and configured as needed.

Are installing companies able to deal with that?

Uwe Schmidt: This poses severe challenges for many installing companies. In commercial storage, expecting quick and easy jobs is unrealistic. We try to provide our customers with the ideal solution, both in under economic and technological considerations, in cooperation with our specialist partners and suppliers, along the entire value chain.

Andreas Lipphardt: Lead time can be up to several months. Then another few months for delivery – especially if we are talking about bespoke battery systems. When using standard components, there usually are no problems with delivery.

But is the preliminary planning phase not also an opportunity to establish trust with the customer?

Uwe Schmidt: Definitely. Trust is everything when it comes to project-based business. In the planning phase, the project has to be considered in its entirety to minimise risks and costs when eventually putting it into operation. You establish trust by demonstrating your technical expertise during the planning phase. This is essential to any cooperation as partners in project-based business. And: Good preliminary planning also has a positive effect on ordering, installation and putting into operation.

Andreas Lipphardt: In domestic storage it usually is much easier to change plans, even while already on the building site. For example, if you decide to place the unit somewhere else than originally planned. For commercial storage this sort of thing is only possible at great cost. When it comes to photovoltaic installations, our industry is just now realising how costly retrospective alterations can become. Back then, many installations were put together in a slap-dash manner. The issues, defects and damage is only now materialising, and that can be quite costly for the operators.

How much storage capacity has so far been delivered and installed by IBC Solar via your customers?

Andreas Lipphardt: A total of 85 megawatt hours, about 45 percent of which is lithium batteries. Lately, the share of lithium cells has been as high as three quarters. And this rise in demand is set to continue for 2018.

What do see as the major shortcomings of installing companies where commercial storage is concerned?

Andreas Lipphardt: Most of all in the readiness to commit to preliminary planning. Many companies simply lack the time or the skills. After all, it can also involve circuitry, or medium-voltage connections. That is the reason why we are expanding the services that we provide to our about 600 specialist partners. On the other hand, there are numerous companies that are perfectly capable to meet such challenges, even without our support. That is up to them to decide.

Uwe Schmidt: After an initial consultation with the customer usually allows a fairly clear assessment of where a system solution might be headed – with or without PV. Also, appropriate tools can help in determining the size of the ideal battery system. Then there are further questions: Where is the system to be located? Would a container unit be the better choice? Is a medium-voltage connection desired or possible? Is the plan to connect an already existing energy management system?

Andreas Lipphardt: That requires extensive experience. Some installing companies have it, others do not. As early as 2012, we established our first 240 kilowatt hours district storage system to stabilise the grid and lessen the need for further development of the grid. The second one with 660 kilowatt hours of nominal capacity followed in 2015. That is something to fall back on.

Are installing companies even capable of providing such planning services? Business in currently booming, and the order books are full – even disregarding commercial storage…

Andreas Lipphardt: That is true, and it raises the pressure that installing companies are under. But if you want to stay in the game, you have to work out a proper strategy. That is the case in any industry, not just storage. And electricians face the added challenge that the building industry is also currently doing well. They are already working at full capacity.

Uwe Schmidt: Furthermore, commercial storage usually involves commissions that are more complex than for standardised PV solutions or domestic storage. Companies will begin to specialise: Some will continue in standard solutions for family homes that involve standard systems, while others will go more down the commercial route. Especially for larger installing companies it will become increasingly interesting to provide comprehensive customer service for their local commercial customers – and to work on acquiring the relevant competences.

How many larger storage systems have you built or serviced in 2017?

Andreas Lipphardt: About 30 to 40 of more than 50 kilowatt hours in capacity, and about half of these were lead-based systems. This is definitely the direction we intend to go.

How significant is lead storage?

Andreas Lipphardt: Very little in the domestic segment, and about 50 percent among larger applications. Southern countries are more suitable to lead acid batteries, because they are less sensitive to higher ambient temperature than lithium batteries. And the technology is familiar, and maintenance is fairly straightforward.

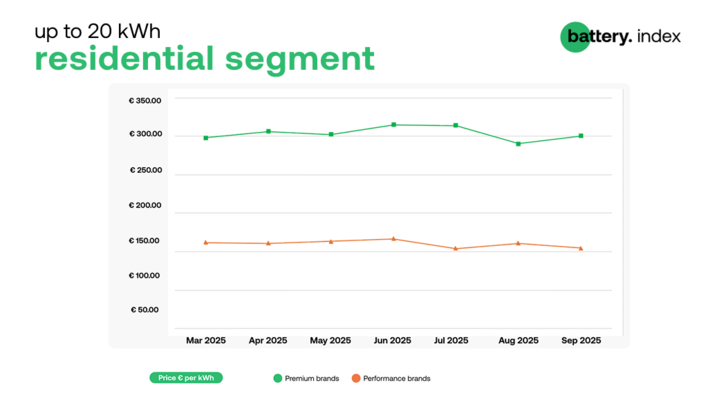

On Prices: How do you predict that the price of lithium storage will develop?

Andreas Lipphardt: For low-voltage systems, we are at around 1,000 euros gross per kilowatt hour. High-voltage systems come in at between 600 and 800 euros. If building larger storage units by combining standard systems, we can achieve 500 to 550 euros gross per kilowatt hour. Surprisingly, container units are slightly more expensive – between 700 and 850 euros per kilowatt hour. Larger 400 kilowatt-hour systems can actually be built for 600 euros per kilowatt hour.

Will this development continue?

Andreas Lipphardt: For the third and fourth quarter of 2018, we are already working on further developing our Solstore 6.5 Li. While fitting into the same cabinet, the use of more advanced cells will allow it to have 50 percent more storage capacity, which will mean that the price per kilowatt hour will come down by another 50 euros. Energy density of the cells will continue to rise.

Uwe Schmidt: In the last three to four years, the price for storage has nearly halved. Today a 10-kilowatt hour unit is about as affordable as a 6.5-kilowatt hour unit was then. Commercial customers, for whom price is much more of a factor than private ones, value this very much. To them, the investment has to be balanced against the savings in electricity costs that it generates.

An important benchmark are the prices for lead storage. Is lithium already competitive here?

Andreas Lipphardt: For lead, the gross price per kilowatt hour is between 320 and 350 euros. If you consider that lead batteries can only be discharged to half of their nominal capacity, lithium storage is almost level.

What could be obstacles that stand in the way of a massive adoption of commercial storage?

Andreas Lipphardt: We are already reaching the limits of our capacities for assembly. Installing companies are urgently seeking trained electricians. On the other hand, the German registry of tradespeople for A-type installations lists about 60,000 electrical companies, only a fraction of which are active in PV or electricity storage. I would estimate less than ten percent. Because photovoltaics and storage are becoming the norm in the field of electrical industries, we need to get these companies involved.

Is vocational training of technicians keeping pace with technological developments?

Andreas Lipphardt: Unfortunately, not. And in the training regime for master craftspeople, photovoltaics – not to mention storage – only play a marginal role. And everyday experience shows how naïve some electricians are when it comes to these topics. They just assume that it is simply a matter of plug and play. But the integration of storage systems is not quite that simple.

The interview was conducted by Heiko Schwarzburger.

Stay informed, get our newsletter twice a week. Register here.

Read more about solar modules.

Read more about solar mounting systems.

Read more about solar energy storage.