- Crystalline panels - mono are the work horses

- Bifacial panels – capturing the light on both sides

- Thin-film solar panels – advantageous in case of heat and shading

- The price alone is not everything

- Prefer strong brands and read the small print

- Leave it – not just the panels – to the professionals

And here come the explanations:

1. Crystalline panels - mono are the work horses

The source material of crystalline solar cells is quartz sand (silicon oxide). This is reconditioned, melted, cast into ingots and cut into slices (wafers). From these the silicon cells are then cut at a thickness of 100 to 180 micrometres. They convert light to electricity.

The crystals in polycrystalline cells have an irregular structure and a blue sheen. Monocrystalline cells are black and consist of one single crystal. They allow for a better electricity yield but are more expensive to produce. For protection, the solar cells are imbedded in plastic foil, covered in safety glass and framed in aluminium. Some panels have a pane of glass on either side (double-glass panels), however, most have a solid sheet of plastic at the back. The rear of the panel also includes a connector with clamps.

Polycrystalline solar cells currently achieve efficiency of up to 20 percent, up to 18 percent as part of a solar panel. Monocrystalline cells now allow yields of up to 23 percent, monocrystalline solar panels achieve up to 19 percent efficiency. However, ventilation is important to avoid great losses in output due to overheating from too much sunlight. At the moment polycrystalline solar panels for rooftop installations produce up to 265 watts, decent monocrystalline solar panels up to 350 watts. (Back to top)

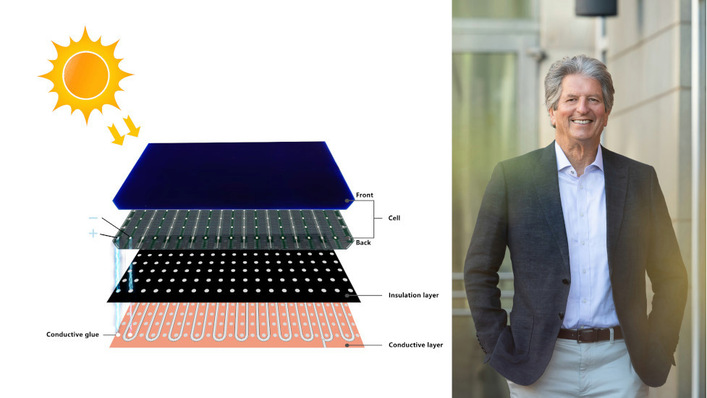

2. Bifacial panels – capturing the light on both sides

A recent development has been bifacial panels where the crystalline cells can make use of the light on both sides. A transparent plastic sheet or a pane of glass on the back of the panel allow indirectly capturing reflected sunlight. With a bright background or appropriate mounting, it is possible to achieve additional yields of up to 25 percent. Such panels produce up to 375 watts, albeit at a higher cost compared to conventional products. (Back to top)

3. Thin-film solar panels – advantageous in case of heat and shading

Thin-film solar panels use an extremely fine layer of electricity-generating semi-conductors. They have a constantly homogenous surface and are available in various shades of colour. A number of manufacturers are offering CIS and CIGS panels, whose brackets made from glass, metal or plastic are coated in copper, indium, selenium and gallium. They are by now managing to achieve efficiencies of around 15.5 percent. More than 17 percent and up to 420 watts can be achieved by Cd-Te panels, coated in recycled and solidly bound cadmium and tellurium. Even though their efficiency is still significantly lower than that of crystalline panels, they can nonetheless achieve higher yields per kilowatt of installed capacity: While crystalline panels can sometimes produce up to 25 percent less electricity when exposed to high temperatures, thin-film panels are much more robust and their drop in performance when exposed to extreme heat is about two thirds less. They also are advantageous in case of partial shading and in the winter, because they can make better use of weak and diffuse light as well as sunlight at an angle; which also means that there is more flexibility when it comes to mounting. In contrast to crystalline panels, they do not necessarily have to be oriented directly at the sun. (Back to top)

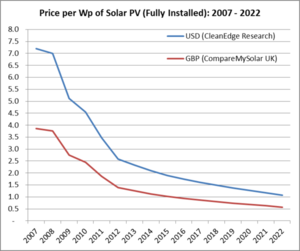

4. The price alone is not everything

Solar panels prices have fallen significantly in recent years. Currently, crystalline panels can be had for about 60 cents to one euro per watt (retail price including taxes). Products from Southeast Asia and Taiwan are the cheapest, solar panels from Korea and Japan are most expensive. Products of European manufacture are somewhere in the middle, price-wise. The same is true for thin-film solar panels. By the time a PV array is fully mounted and installed on your roof, you should expect to pay between 1,200 to 1,700 Euro per kilowatt. But low price alone is not everything. Be realistic in your calculations: How long will the panels and the installation produce the expected output? What certificates are there and what is the warranty like? Is it to be expected that the manufacturer will go bankrupt anytime soon and you will then be left alone with any damages? What service is available locally? (Back to top)

5. Prefer strong brands and read the small print

Rule of thumb: Buy solar modules brand products that are certified by the TÜV and other institutions; preferably from manufacturers that can be expected to be in business for the foreseeable future. Prefer panels of high performance and wattage (at the same dimensions), because that will allow you to yield more solar electricity from your roof and save on installation costs. If you live in an area with high rates of snowfall, it is recommended to consider the more stable double-glass panels. But always take the time to read the small print – especially the panel specifications. A key point is the temperature coefficient, which specifies by how much the output increases or decreases with every degree of difference from the standard temperature (25 degrees Celsius). With every degree of temperature increase, the output goes down by that factor, and vice versa. Take note of the specified output tolerance: It denotes the width of the scattering of the panel’s nominal output on delivery. Always choose panels with a positive tolerance, i.e. output should only deviate upwards. Most manufacturers grant a voluntary performance warranty, which should ideally look like this: At least 90 percent performance within the first ten years and 80 percent after another ten years. The law only specifies a warranty (liability for being free of defects) of two years. (Back to top)

6. Leave it – not just the panels – to the professionals

Even if you have basic skills and knowledge in photovoltaics, please always rely on a qualified installation company. And that applies not only to selecting the solar panels that are best for you, but also the planning and installation of the entire PV installation as well as a matching storage system. After all, every component has to complement every other one and be properly installed, to give you the highest yield over many years to come: The best solar panels available are of no use to you, if the PV installation is wired up the wrong way or has been equipped with a sub-standard inverter. Also leave the cleaning of your solar panels and your solar generator to the professionals. (HCN/HS) (Back to top)

To get deeper into business, read:

Solar modules: costs, prices and finance at a glance

Solar modules: keep up with the latest product news!

Solar modules: Useful tips how to secure your PV investment

Solar modules: our insight stories at a glance

Solar Modules: our expert’s interviews at a glance