The Swabian module manufacturer Nice Solar Energy has set a new efficiency standard in thin-film photovoltaics. The company has increased the efficiency of its modules, which generate electricity with a semiconductor layer consisting of copper, indium, gallium and diselenide (CIGS), to 17.6 per cent – and on the module surface at that.

This is particularly important in thin-film photovoltaics. Here, the differences between the efficiencies achieved on small surfaces in the laboratory and then later on the scale of a module are particularly large. This is mainly due to the fact that there are not only interconnection losses as is a challenge in crystalline silicon technologies, but also during the consistent application of the semiconductor layer.

Optimised manufacturing process

Nice Solar Energy has already gained a lot of experience at this point. Therefore, the new efficiency record is also based on a combination of this existing experience in the production of thin-film modules and some improvements in the production process. In particular, the company has worked on better and more uniform deposition of semiconductor layers and has implemented new concepts for cell interconnections.

Elsewhere on pv Europe:

Organic solar has also set new efficiency records recently.

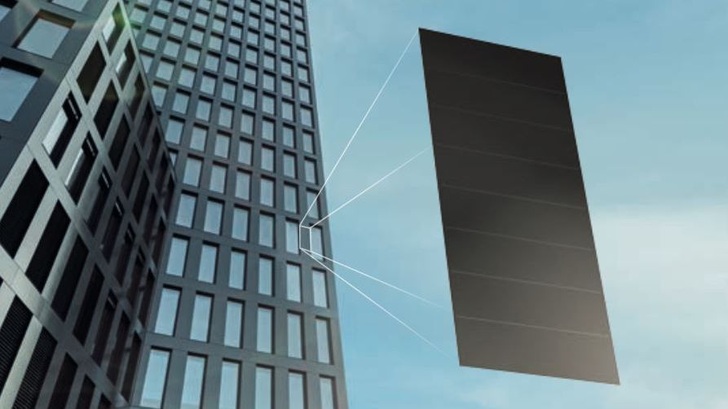

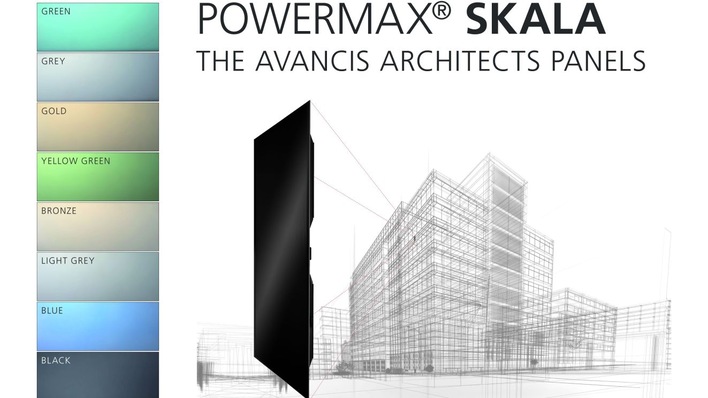

With this new record, Nice Solar Energy not only wants to set itself apart from the competition in the CIGS sector. Rather, the Swabians want to advance the technology more strongly than crystalline silicon photovoltaics and establish it on the world market in the long term. After all, it has a number of advantages, especially for building-integrated photovoltaics. They can cope better with a less perfect alignment to the sun. They also have a better temperature coefficient, i.e. they lose less output as temperatures rise compared to crystalline modules. (su/mfo)