Solar cells. Lithium cells. Now the next ‘cell-based technology’ is on the horizon: In recent years, fuel cells have made some major strides – more or less without anyone noticing. The technology is getting to the markets, even though a number of players are not realising its potential. For instance, the building services giant Vaillant has recently announced at the trade show ISH Frankfurt/Main that they would stop developing stationary fuel cells. The company headquarters in Remscheid let it be known that to them this technology had no future, and therefore all development would cease.

Truth be told: The engineers at Vaillant were unable to design and build a fuel cell of sufficient service life that was both switchable and capable of being extended modularly. Vaillant made their name in oil- and natural gas-based heating technology. That makes it hard for them to see a future for themselves in electricity. It is a little like the problem that utilities are having with their fossil fuel power plants – just less so by a few orders of magnitude. Until very recently, no one was expecting renewable electricity from wind and solar to make the cut.

Severe misjudgement

Such severe misjudgements have been well-known from the solar sector: Shell, Siemens and BP started out on the road to PV, but never made it past tentative attempts. And Vaillant is no different: The engineers were unable to grapple with the technology. But what is worse is that their bosses have not got the message that integrated energy is already established in the market. Building services will no longer be conceivable without fuel cells in the future.

Their competitors at Viessmann in Allendorf have gone a different way and were more successful: At Viessmann they use a fuel cell made by Panasonic that has already been installed by the thousands in Asia. Unproven technology? The people at Panasonic must have been heaving with laughter when they read Vaillant’s press release.

Viessmann has already sold around 1,000 of their fuel cell heating units Vitovalor 300-P. So far it has been available in combination with a module-based 19 kilowatt gas-fired water heater. Early this year at the ISH, Viessmann presented their new system comprised of a fuel cell (750 watts) and a gas-fired water heater that produces up to 26 kilowatts in thermal output.

A million operating hours in the field

Solid Power from Heinsberg near the German border with the Netherlands is now operating more than 700 of their Bluegen fuel cells in the field. This small electricity generator has an output of 1.5 kilowatts and, when running continuously, can produce about 13,000 kilowatt hours per year. In contrast to Viessmann, Bluegen produces almost no waste heat. The efficiency for electricity generation can reach up to 60 percent. It is possible to run a small business with a high electricity demand on this unit, especially if it is combined with the use of PV.

In four years, the Bluegen units have accumulated over one million operating hours. The new funding programme of the German government (KfW 433) offers very lucrative subsidies for fuel cells. These can sometimes start paying off within seven to eight years.

Especially economical in combination with EVs

Fuel cells are especially economical when they cover high electricity demand over a long period. “Think of bakeries: Their ovens are heated electrically, so they have a high surplus of heat, Jürgen Hohnen, master electrician at Solid Power, says. “But buying in power is expensive and so a fuel cell that is current-integrated and -controlled makes sense.”

Classic cogeneration units create too much waste heat. They would not be economical in a bakery, and because the heat cannot be utilised, such a unit would not be sensible. Jürgen Hohnen and his 22 staff have fitted over 35 Bluegen units in North Rhine Westphalia.

His company has specialised in fuel cells, string cogeneration units or classic motor-driven cogeneration units of up to 50 kilowatts in electric output. They are also specialist partners of the Austrian boiler manufacturer Ökofen, who focus on wood pellet heating systems. Early in the year, Ökofen came out with a pellet-fired cogeneration unit with a Stirling engine, which generates both heat and electricity – for those darker months of the winter when PV alone is not sufficient.

Many customers would like to combine a fuel cell with an EV – if not right away, then at least very soon. “For that to happen, the unit has to produce a decent amount of power,” Jürgen Hohnen says. “A BMW i3 can be charged at six amperes, that is equivalent to two kilowatts. A Tesla can be supplied with 1.2 kilowatts. It is in the garage during the night and that is when the fuel cell would be charging its batteries. Or take commercial customers such as home care service providers: They are keen to do short distances using EVs, and a fuel cell is excellent for that.

The market is still in its infancy

Jürgen Hohnen sees fuel cells as still being in its infancy: “Our customers are private persons that know what they want from this technology,” he confirms. “Associations of property owners and commercial enterprises are also customers of ours – up to 50 kilowatts. Our units usually run on low voltage.”

He sees products such as Bluegen as well-engineered. “They have stood the test of time. We have concluded that such fuel cells bring more benefits in well-insulated buildings,” he recommends. “A gas- or Stirling-powered cogeneration unit cannot get rid of its waste heat under these circumstances. This limits the number of hours that the unit can operate at full load and thus also the power yield. Law offices or doctor’s surgeries tend to have a high demand of electricity for running computers and servers, while there is little need for heating. We once fitted a fuel cell to an object that already had a running cogeneration unit. They wished to produce more of their own power, but had no further need for heating.

Solar power into hydrogen

Fuel cells bring full independence: both for private and commercial customers. It is only a matter of time until larger companies will also discover the benefits this new technology can have for them. In only a few years it will actually be possible to run a building in off-grid mode – even without being connected to the gas supply.

The Berlin-based company Home Power Solutions (HPS) presented their all-in-one system Picea at the Intersolar in Munich, which is able to self-sufficiently supply a small private house. Solid Power’s Bluegen system still runs as a grid-connected generator, just like standard solar inverters. Picea is designed from the ground up as an off-grid solution. Any connections to grids or supplies are unnecessary. This new form of self-sufficiency is becoming more important to many people and they are willing to spend money on that. Picea ensures that a family residence can be fully powered just with PV and a fuel cell.

Eight kilowatts, single-phase

The core of the system is an electrolyser and an elaborate management system that balances the demand of the house between generation and storage. The system was first presented at the ISH in Frankfurt, then at the Hanover Fair and also at the Intersolar in Munich. “Picea can generate up to eight kilowatts of output – the power is fed into the building supply as single-phase electricity,” Henrik Colell, one of two CEOs of HPS, explains. “For short periods the system can produce up to 20 kilowatts. It does not have to be connected to the power grid, so it is fully off-grid capable.”

So far the inverters of the common solar installations or fuel cells today require connection to the grid. They synchronise their frequency in order to be able to feed in any power surplus. By contrast, Picea is fully geared towards the self-sufficiency of the customers. It is as if the system created an island. Surplus power from the PV array are converted into hydrogen by the electrolyser and stored for the winter in a tank. In the darker months, a fuel cell turns it back into electricity and heat. A solar battery is there to meet short-term demand.

Field trials have started

Picea is a combination of PV and fuel cell technology. So far, two pilot installations have been built and first field trials have started. The key target group is people who own homes. Instead of a tank for gas or fuel oil, as was formerly the case, now a tank for the hydrogen is installed. “Its size depends on the size of the solar array and the expected electricity demand during the winter,” Zeyad Abu-Ella, the other CEO, explains. “The tanks are designed to hold 300 bars (4,351 psi) and certified according to German safety standards. There will not be any issues over insurance.” These hydrogen tanks do not require a special gas warning system or forced ventilation system, in other words, they are actually hermetically sealed.

The system is currently dimensioned for an annual electricity demand of 3,000 to 6,000 kilowatt hours. The hydrogen storage tank requires between four and seven square metres of space, i.e. can be housed in a car port, a small annex or even underground. It can be installed like any other liquefied gas tank and is about head-high. The compact unit inside the building requires three square metres of space.

Dimensioning the system happens through a software developed by HPS – the customers are provided with an app to control the unit. “We want to sell our unit as a complete package, rather than for individual projects,” Henrik Colell explains. “The units should come off the production line in order to keep the cost low.” As there are only prototypes, HPS does not yet quote any prices.

Standardised interfaces

Connecting to Picea happens exclusively through standardised interfaces. The electrical wiring from the PV array and to the building grid are all in line with the usual requirements. The hydrogen tank is installed and connected by a gas specialist. On top of everything else, Picea makes it possible to install a ventilation unit in the house in order to efficiently use waste heat. The air flow is also controlled by Picea’s management system. Both are controlled by the HPS system via an integrated energy manager.

Last but not least: The unit also needs a water connection, since the hydrogen is generated directly from water by the electrolyser. Picea does not operate via natural gas and a reformer to generate the hydrogen. Just water and solar power are required. This also means that the supply centre works without being connected to the gas supply.

The electric efficiency of the fuel cell is between 55 and 60 percent. If the integrated ventilation system that includes a cross-flow heat exchanger and a moisture recovery system is factored in, that efficiency goes up to over 90 percent. The fuel cell is even capable of being switched on or off according to demand. Other fuel cell units are usually designed for constant operation, i.e. they work as base load systems.

Self-sustaining control

Not so with Picea: During the summer, the PEM fuel cell usually only turns on when there just is not enough solar power. Not until the transitional period does it come on to meet the house’s electricity demand, and produces an output of up to 1,5 kilowatts. During the winter, it can be expected to run more or less 24/7. In that sense, Picea is a current-regulated system, with the waste heat being used only via the ventilation system for the living space. The unit completely controls itself without any input from the outside. And it works nearly silent. All of the power electronics, including the off-grid-capable inverter, is integrated.

For short-term and night demand, the system has a built-in battery. The first prototypes have been equipped with lead gel batteries with a capacity of about 25 kilowatt hours. “That is what we calculated to be the most economical solution,” Zeyad Abu-Ella says. “We control the batteries with care in order for them to last as long as possible. In the future we might consider using lithium ion batteries, but that will depend on the prices.”

Interesting service concept

HPS are starting out with an interesting service concept. The system cabinet is the same for all versions. All components are designed to be slide-in modules that are easy to exchange and the system leaves the factory pre-wired. “In our service agreement we take the risk of the fuel cell stack having to be exchanged as time passes,” Henrik Colell explains. “Exchanging the hydrogen components is simple and can be done by any qualified installing company.”

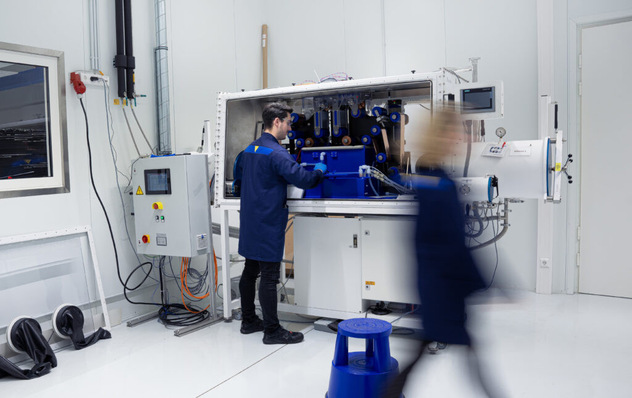

HPS is a spin-off company of Heliocentris. Developing this compact units goes back all the way to 2012. Back then they started out with three people. Today, over 35 staff are employed in the workshop and the labs at the Science Park Berlin. “Following the successful launch of our pilot installations, it is now our goal to further test our units, introduce them into the market and get up to large volumes as soon as possible,” Henrik Colell predicts.

Picea will be ready for delivery in 2018. “Until late 2017 we would like to get as many partners and interested building developers on board as possible,” he continues. “That can include installing companies that want to test and install our system; that can also be providers of prefab houses, to name just one example.” It is currently not the plan to go through specialist retailers, but rather to directly sell to installing companies. Henrik Colell: “We are taking orders from late 2017.” (Heiko Schwarzburger)

Read more about energy storage systems.

Stay informed, get our free newsletter twice a week, register here.

More useful information:

https://www.pveurope.eu/solar-storage/solarwatt-and-fronius-train-new-installation-partners-uk