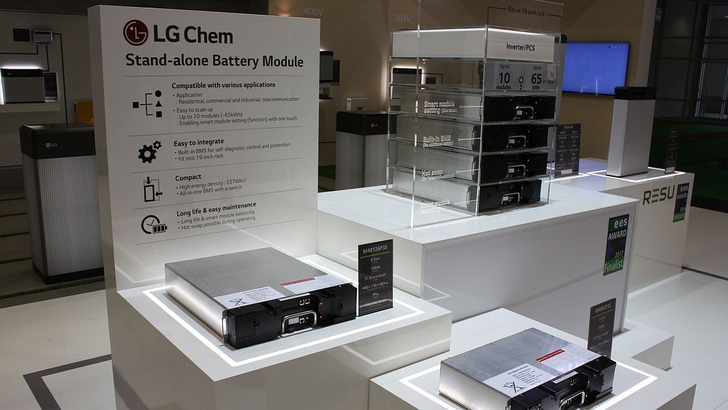

At last year’s Intersolar, LG Chem had presented their new Resu series of storage units, for which they won an award of the storage show EES. This year, they showed a new battery module that is designed as a stand-alone system. This DC battery stores 6.5 kilowatt hours of solar electricity, and up to ten of such modules can be combined to form a battery of 65 kilowatt hours.

And although the same JH3 cell as for the Resu units is at the heart of this new system, it is clever for its high degree of standardisation as well as its control electronics: multiple modules are wired up according to the master-slave principle and connected to the inverter or charging controllers, which then control them directly.

Quickly build up large storage units

Thus: Using these battery modules, any system integrator can very quickly put together large-scale storage units and adapt them to the needs of his customers. Even though LG Chem do not intend to get into the market for commercial storage, as they did by introducing their Resu units to the market for private end customers last year, their SBM (stand-alone battery module) should soon allow them to become the leading supplier to providers of commercial storage. Because the JH3 cell, which is constantly being enhanced, has a great energy density, has an application in the automotive sector most of all. The next generation – JH4 – is soon to follow and it is to be expected that the energy density will again rise sharply.

The cells, both within the battery module and among the modules, are controlled in such a way to enhance service life. In case of weaknesses or defects, the affected battery module can be removed from the battery rack and replaced without difficulties.

Economies of scale

This battery module will be very soon be manufactured in large volumes. This will allow LG Chem to massively reduce the price per unit in order to make the batteries more inexpensive. This is hard to achieve with individual fixed-output batteries as in the Resu series. And even though LG Chem were able to sell 5,000 units last year, achieving really high volumes is only possible if all storage units are based on a standard and easily integrated battery module. The Chinese battery manufacturer BYD, Panasonic from Japan and Samsung, from Korea like LG Chem, are also following this path.

The voltage level of the battery modules is at 51.8 volts, they run on 42 to 58.8 volts. Because of their high energy density of 227 watt hours per litre, the individual SBMs are very compact and easy to handle. They are controlled by a CAN 2.0B or a Modbus 485. Another 3.3 kilowatt hour variant still manages to achieve an energy density of 197 watt hours per litre.

Refining cells at a higher level

That way, it will in the future make less sense for storage suppliers to order separate cells from LG Chem: They will buy in complete battery modules and integrate them, thereby making the in-house manufacture of modules redundant.

LG Chem will thus take over that part of the value chain and refine their cells at a higher level. The prospects are enormous: The lithium ion storage market could expand to 16 gigawatt hours by 2020, compared to three gigawatt hours in 2016.

LG Chem demontrated their desire to take centre stage in this segment by the quality of their submission to the EES Award: Few of the submitted proposals could match theirs in terms of scale and value when it came to technical details on innovation, test reports and certificates. (HS/HCN)

Stay informed, get our newsletter. Register here: http://www.pveurope.eu/Newsletter

More useful information about energy storage systems

Solar panels:

Choose your right solar panels

Electric cars:

Learn about electric cars to make more use of energy storage