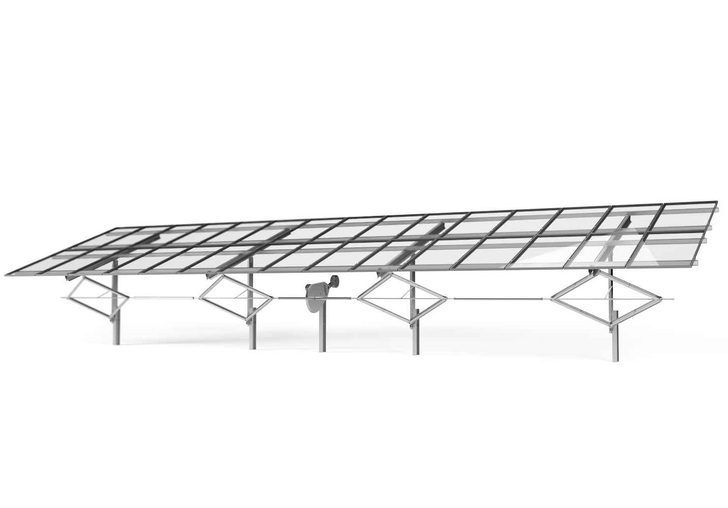

It carries up to three modules portrait, can handle 324 modules per row and provides a yield increase of up to 25 percent compared to south-orientation elevated tracks. All components are extremely sturdy in spite of their light-weight construction. The single axis design from Mounting Systems requires low maintenance and is reliable.

Siemens motors drive the torsion axis, which moves effortlessly even in very uneven terrain. The structure is based on project specifics and can withstand wind speeds of up to 250 kilometres per hour and snow loads of up to half a meter. The sturdy mechanics can even be used in earthquake-prone regions. We provide a warranty of up to 25 years for the individual components. Remote maintenance further lowers operating costs.

The individual elevated tracks are self-locking at any angle. This prevents elastic distortion of the entire system and saves energy. The design is optimized for transport, and the preassembled components save project developers time. The installation technicians literally only connect the tracker on site. The optimal design combined with the specific materials reduces the amount of steel required per kilowatt output. A plant with two megawatt output only needs one switch cabinet.