Conducting the tests, the VDE Testing and Certification Institute (VDE), an internationally accredited testing institute for electronic equipment, fired multiple 45 millimeters-wide ice balls at 110 kilometers per hour at Solar Frontier’s panels. Standard industry tests usually only cover up to 25 millimeters-wide ice balls fired at 83 kilometers per hour.

No problems in winter storms

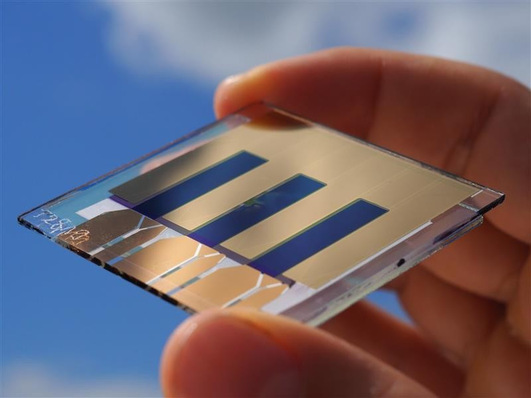

Solar Frontier has announced its panels withstood the tests, confirming their viability for use by homeowners and businesses in regions which frequently experience damaging winter storms. The panels are made of a thin film composite of copper and indium (CIS). The front side is covered with glass.

Solar panels are subjected to a host of mechanical stresses on a daily basis and are expected to endure these stresses over at least two decades. Solar Frontier’s solar panels have also passed tests that demonstrate they are suitable for a host of other challenging environments, including ammonia-heavy areas (i.e., animal farms or areas with lots of birds), salt-mist areas (i.e., along the coasts), and in areas with sandstorms (i.e., deserts).

Not a single human touch in production

Behind the durability of a Solar Frontier panel is its solid glass surface, its aluminum frame, airtight sealant, and the precise consistency of its manufacturing process. All Solar Frontier panels are manufactured in a fully-automated production plant in Japan, where not a single human hand touches the module until the panel’s final quality inspection.

Solar Frontier has to date shipped over 3 gigawatts of its solar panels – enough to stretch halfway across the globe when lined up – to 50 countries around the world.

Its solar panels belong to a technology group called CIS, denoting key ingredients copper, indium and selenium. In addition to their quality advantages, CIS solar panels are able to generate more electricity in real-world conditions compared to conventional crystalline silicon solar panels. (HS)