"I have seen so many problems that common mounting systems for substructures of solar panels with roof penetration bring. Above all, penetrating water, but also a lack of stability and an overall high maintenance effort, "remembers Guiseppe Engheben. The resolute 49-year-old owner of industrial rooftop supplier Grondal srl in Castiglione delle Stiviere in the neighborhood of Garda lake developed a solution two years ago. The patented support system EGA, which is suitable for a wide range of corrugated roofing panels and metal sheets, especially for industrial buildings. The main trick is its fixing, using the same screw that anchors the metal sheet or panel to the underlying roof frame support. "In this way we avoid additional roof penetration," emphasizes Guiseppe. As a result, the resistance is by far superior respect to the traditional systems of panel piercing with thicknesses of 5-6-7-8-/10 th.

Prevent water infiltration

“Another very important characteristic is the final solution to water infiltration, caused by the usage of different types of seals available at the market, compared to the large number of punctures usually required”, Guiseppe explains. Another key benefit: The simpler design allows faster assembly, which is a major factor in system cost reduction. "In this way, we can reduce the share of installation costs from the current 35 percent to 20 percent," says Guiseppe. Furthermore maintenance costs are reduced, he adds. The fixing system may be produced in different thicknesses, up to the installers different requests. It can be combined with most standard mounting rails and module racks.

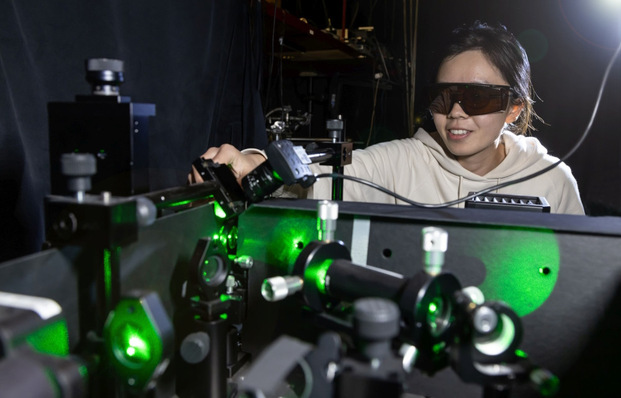

No-mold poduction process

EGA system is manufactured by high-technological machines in a no-mold production process, thanks to the close cooperation with corporate partner in Veneto, where Guiseppe had the invaluable opportunity to assist the entire production process. There, galvanized or stainless-steel metal strips are cut to size, drilled and formed into clamps in different thicknesses and sizes. Senior boss Rino Zocca is particularly proud of the new laser forming machine in the rear section of the production hall, by which he’s reached the highest level of precision.

Screws from UBB

The screws for the EGA system are also manufactured in the region by UBB. Wire coils are used to cut and turn a wide variety of standard and special screws, especially for roof applications. Various manufacturers are supplied. Coated steel is used for the EGA system, which does not rust, explains employee Federico Maffezzoni. "Photovoltaic applications are playing an increasingly important role for us," adds CEO Diego Bertolotti.

In any case, Guiseppe Engheben does’nt have to worry about lack of demand. Last year he equipped industrial roofs projected for more than 10 megawatts of PV-installations with his EGA system. And the list of customers is getting longer. (HCN)

Stay informed, get our newsletter twice a week. Register here.

More useful information:

https://www.pveurope.eu/solar-modules/commercial-solar-self-consumption-italy-pays