Europe is seeing an increasing number of photovoltaic systems being installed on flat roofs, because many commercial operators are interested in their self-consumption and related tax advantages. They usually install the systems in an east-west orientation, because in this case the roof can be covered with around 30 percent more solar panels and the electricity can be produced more evenly.

East-west systems also have the advantage that they expose significantly less surface area to the wind and can therefore be designed with much less ballast than, for example, arrays that are only inclined southwards. Since manufacturers have also optimised their assembly systems aerodynamically over the past few years, solar systems can now be installed on flat roofs where this was not previously possible.

Two concepts: either rails or struts

Whether a solar power array can be installed on a flat roof depends not only on the ballasting and the dynamic loads caused by wind and snow, but also on the surface quality of the mounting system and the insulation.

For flat-roof mounting, two concepts are usually distinguished: While the solar panels for pointed support systems rest on local support surfaces, linear systems distribute the loads over (continuous) rails.

Pointed systems are usually more inexpensive because they require significantly less material. In addition, these systems allow rainwater to drain off easily. At first glance, it would be assumed that linear systems distribute the load more evenly over the roof cladding.

Combine the concepts

However, since the manufacturers of these systems use building protection mats in order to allow water drainage – provided that the gaps are not clogged by coarse dirt – this concept also results in more selective loads. Furthermore, a linear load approach only partially corresponds to the real-world, uneven accumulation of snow and the very localised wind gusts at the solar modules

The engineers at the Ernst Schweizer AG based in Hedingen near Zurich combine the advantages of both concepts. In late 2014, the company took over the assembly systems for east-west-oriented flat roofs (MSP-FR-EW) and pitched roofs (MSP-PR) from the construction supplier and tool manufacturer Hilti AG from Liechtenstein.

Panels with up to 96 cells

In 2015, the company developed its own MSP-FR-S for solar systems inclined to the south and MSP-TT for trapezoidal sheet metal systems. The substructures are made of high-quality aluminium and stainless steel with a protective layer of polyester fleece. They are suitable for flat roofs with foil, gravel or bitumen roofing membrane and framed solar panels made up of 60 and 72 cells. For the east-west version, they are also suitable for panels made up of 96 cells.

Variable base plates

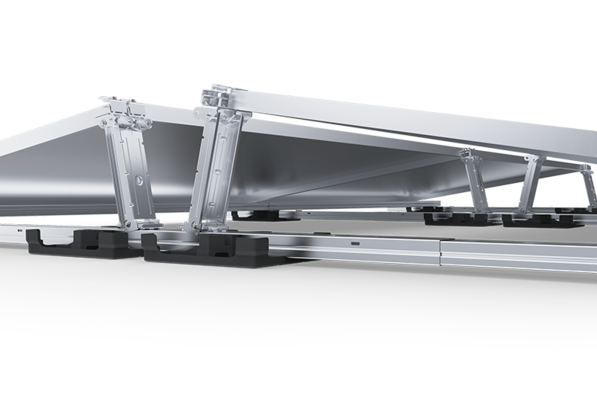

These mounting systems make do without long, narrow floor rails and instead use base plates with a variable contact area of up to 0.3 square metres per support. Low and high supports are clicked onto the base plates and connected with the struts in a north-south and east-west direction.

These connectors contribute to better stability of the flat roof system without the load being transferred via the solar panels (block formation). The Ernst Schweizer AG offers six different versions of the base plate, which are 25 centimetres long and vary in width from 13.5 to 118 centimetres. This offers a multitude of solutions for insulation materials that can withstand different loads.

Saves material, time and money

This concept saves material, time and money. At the same time, it reacts to the condition of the roof (long-term compressive strength of the insulation material with a maximum of two percent compression) and to different loads from wind or snow.

Under favourable aerodynamic conditions, in projects with low gust velocity pressure and a certain contiguous formation size, east-west systems do not require additional ballast. This concept allows water to drain easily under all conditions. (Dr Helge Hartwig)

Dr Helge Hartwig is Head of Sales and Technology for PV mounting systems at Ernst Schweizer AG.

Read this, too:

http://www.pveurope.eu/News/Installation/Bespoke-solutions-for-tricky-flat-roofs

http://www.pveurope.eu/News/Installation/Module-installation-Stable-systems-for-all-roofs

http://www.pveurope.eu/News/Installation/Sjef-de-Bruijn-from-Ernst-Schweizer-AG-We-have-to-be-very-efficient

Stay informed, get our newsletter twice a week.

Register here: http://www.pveurope.eu/Newsletter

Read more on PV in Europe:

http://www.pveurope.eu/News/Installation/Advanced-mounting-solutions-for-British-and-Irish-roofs

http://www.pveurope.eu/News/Solar-Generator/PV-Guided-Tours-More-roofs-fewer-parts

http://www.pveurope.eu/News/Installation/Solrif-in-roof-systems-for-housing-projects-in-England

Read more about solar modules.

Read more about solar energy storage.