The module backside made of polyethylene terephthalate (PET) on which mono or polycrystalline solar cells are laminated is largely responsible for the weight reduction. The tried-and-tested material is also used for rotor blades in the wind industry as well as in shipbuilding and automotive engineering and is particularly cost-effective due to its high production volumes. Product development and support from Opes are based in Germany, production is located in Changzhou, China.

Due to the Fraunhofer CSP the conventional crystalline solar modules weigh around 60 grams per watt. O-Lite Plus modules weigh only about 20 grams per watt. This corresponds to a weight reduction of two thirds. The costs of the new frameless module in series production are on a par with those of conventional modules.

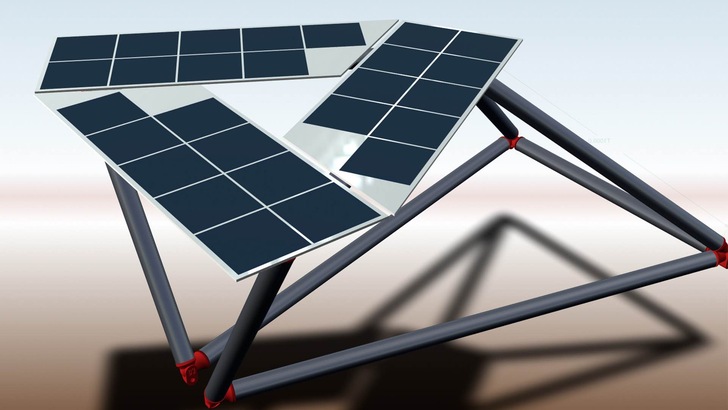

The possibility of producing curved modules and their low weight, O-Lite Plus modules are suitable for weight-sensitive areas of application such as vehicles, boats and small devices, which also place high demands on durability. Due to new and optionally usable variants of junction boxes and connectors, the modules can be plugged together in a modular manner. The module concept was developed together with the Fraunhofer CSP in Halle. (nhp)

Get to know more about solar modules.

Stay informed, get our newsletter twice a week.

Register here: https://www.pveurope.eu/newsletter