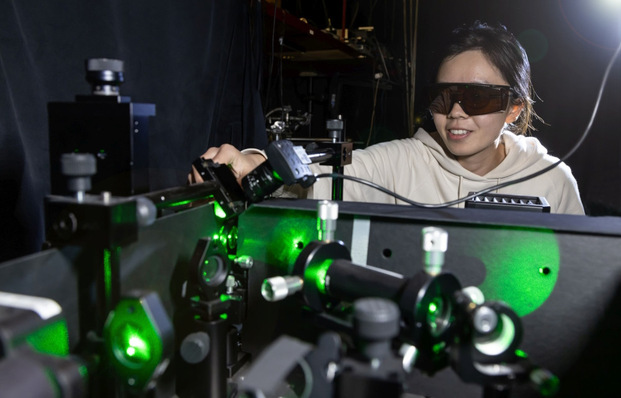

The scientists at the Center Suisse d'Electronique et de Microtechnique (CSEM) in Neuchâtel have developed a process to provide high-resolution images to solar modules. With the new Kaleo technology, the developers tie up to the white solar module, which they presented two years ago. This solution consists of a special foil placed between the solar cells and the cover glass of the module. Not only white modules can be produced, but all colors are possible.

Film between solar module glass and solar cell

Kaleo technology is also based on a film that is laminated between cells and cover glass. Even if the developers for Kaleo take another film, the principle is similar to that of the white module. First, a high-resolution photo is printed on the film with special colors. It is then placed on the back of the module cover glass. The other manufacturing steps are similar to conventional industrial processes for the production of solar panels. After the module is laminated, only the printed photo shines on the surface. The solar cells behind it are no longer visible.

Address architects and create added value

As with any color or printed module, the Kaleo technology is not without performance degradation compared to a blank standard module. The Swiss developers calculate power reductions between 10 to 40 percent. “The technique enables to use additional surfaces for electricity generation, that could not be utilized yet. To that extent we see a 100 percent in solar power production for those new application areas”, CSEM speaker Florence Amez-Droz told pv Europe. The researchers see Kaleo technology as a further instrument that they can use to help architects put more emphasis on photovoltaics as a design element for facades and to promote building-integrated photovoltaics. Further applications they see in using the printed modules as billboards or for company logos. “This can compensate higher costs and create substantial added value”, Amez-Droz says. She is calculating additional costs for the printed modules in series-suitable production of around 30 to 50 percent.

Energetic faces exposed

The CSEM has produced ten prototypes with portraits taken by photographer Guillaume Perret. Two modules each have a portrait. These five large-area photographs between module glass and solar cells are currently exhibited in the garden of the Banque Cantonale Neuchâteloise (BCN), where they can be viewed on request. They are completely wired so that the bank, which has financially supported the project, can use the electricity directly. The system is supplemented by three collectors with optical illusions on the facade of the building and remains installed throughout the summer.

“The distribution is technically possible from now on, interested partners are welcome to contact us”, Amez-Droz says. (HCN)

Stay informed, get our free newsletter twice a week, register here

More useful information:

https://www.pveurope.eu/solar-modules/facades-will-become-complex-intelligent-organisms