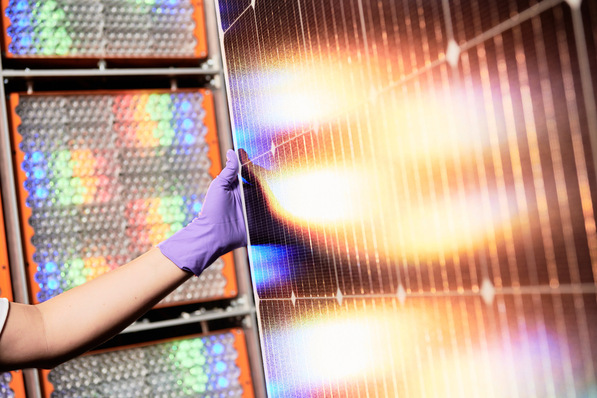

Some are saying that thin-film solar panels are finished. Others are convinced that their time is ahead: Even though crystalline solar panels are dominating the panel market by 90 percent, suppliers of CIS panels continue bringing interesting innovations to the market. The world’s largest manufacturer is Solar Frontier in Japan, who are this year is extending their range of thin-film packages in terms of roof shape and size.

The PowerSets consist of high-performance CIS panels as well as matching electric components. Both the turbo inverters and Kostal’s new Piko inverters were optimised to fit each of the set sizes.

Inverters delivered by Kostal

The new PowerSet Maxi is supplied in all output sizes between 4.8 and 9.9 kilowatt, and there is also a three-phase Piko inverter by Kostal Solar Electric that has two MPP trackers. The PowerSet Maxi’s second MPP tracker makes for a very simple system solution for large domestic roofs involving two strings, which is very quick to plan and install.

The new PowerSet Mini on the other hand was specifically conceived for smaller roofs. It consists of 12 panels and produces an output of two kilowatts. The matching ‘mini’ inverter is single-phase. These two new versions complement the already existing PowerSet Turbo that is available from 2.4 to 8.2 kilowatts – with either a single- or three-phase inverter.

Suitable for roof-top installations

CIS panels have yet to catch up to the high efficiency per surface area of their mono-crystalline rivals, but poly-crystalline panels have practically lost their advantage. Especially because thin-film panels are better at coping with low light and shade and are have less decline in performance due to high temperatures in summer.

Solar Frontier’s PowerSets are suitable for domestic roof-top installations of more than 15.6 square metres in surface area. Because they are variously configurable, they can be installed on top if very different roofs and at very different inclinations.

Monitoring included in the package price

All PowerSets have a 10-year warranty for the entire system. Also included is an integrated and free-of-charge monitoring of the installation. If a PowerSet is laid out and installed to allow for the characteristics of the CIS panels, the yearly yield per kilowatt can even be higher than that of crystalline panels.

“In expanding our product range to include domestic roof-top installations, we are reacting to the strong demand in the market and are giving our installation companies more variety and freedom of choice,” Wolfgang Lange, CEO of Solar Frontier Europe comments. “This provides our customers with even more individual solutions for their roofs. And they’re easy to install.

Two megawatts for Thyssen Krupp

For the commercial segment, Solar Frontier offer larger-scale installation blocks as standard packages, which can be combined to fit roofs of any size. For instance, Thyssen Krupp Materials in The Netherlands had a total of 2.3 megawatts installed on the roofs of their storage depots.

The project which is situated in the towns of Veghel and Zwijndrecht comprises two roof-top installations on top of storage depots. Including a total of 30 inverters and 13,472 CIS panels, it is one of the largest solar projects in the Netherlands. The panels were delivered starting May 2015 and installed in June of that year. The generators were already connected to the grid in July. Between July and November, the installations produced six percent more solar electricity than expected.

A decisive factor was the reliability of CIS panels in an ammonia-rich environment: Thyssen Krupp Materials’ 2,970 square metre storage depot in Veghel is close to the breeding grounds of sea gulls, bird droppings are a problem for owners of the solar installations, as it affects the performance of the panels. Solar Frontier’s CIS panels are certified ammonia-resistant and perform well even in such an environment.

Low costs for setting up new factories

While the market for small roof-top installations is dominant in these parts, elsewhere, greenfield solar parks are booming. First Solar in the US is the leader in terms of cost. They produce and install thin-film panels made from cadmium telluride. With their CIS panels, Solar Frontier is also successful in this segment, because the process of depositing the absorbers to the metallic rear electrode can be fully automated.

Just the factory in Miyazaki on the southernmost main island of Japan churn out one gigawatt of CIS panels per year. By the end of the year, the company has announced that they will build a new factory in the Tohoku region to the north of Tokyo. The domestic market is booming and globally the demand for thin-film panels is also growing rapidly. Per degree in increased temperature, they decline in performance much less than crystalline cells made from silicon wafers.

That means that thin-film panels generally produce better yields in warmer climes. In places where sufficient space for solar parks, thin-film is beginning to have the edge. It costs less than one US dollar per watt of annual output to establish a factory for CIS panels, whereas investments in new factories for crystalline panels costs about four times that. Primarily, it is producing the silicon cells that is much more complex and expensive.

Record-breaking panel from the lab

And the engineers in Miyazaki are already one step ahead: Late last year, they presented a record-breaking panel with an efficiency of 22.3 percent. The prototype was very small – just 0.5 square centimetres – but in a few years, the results of this research will influence mass production, including further increases in efficiency.

That will make it hard for manufacturers of crystalline cells and panels to grow as fast as the thin-film segment. Satoru Kuriyagawa, chief technology officer at Solar Frontier, held out the prospect that “this most recent success will bring us ever closer to our long-term goal of exceeding 30 percent with CIS panels.”

Solar Frontier has developed this cell using the same coating process followed by selenisation which they are using in mass production. This allows them to disseminate all of their recent advances into all future sites of production. For example: Some of the technology that was employed to develop what was in April 2014 Solar Frontier’s record holder at 20.9 percent, is already being implemented at the Tohoku factory. The panels produced there now are 14.7 percent efficient. (Heiko Schwarzburger)

Did you enjoy reading “Solar Frontier is speeding up the pace in CIS module technology”?

So read this, too: “First Solar new 365 W Series 5 modules: significant further variable BOS cost reduction through easier installation”.

Or may be, this expert’s tips: “7 tips: Cleaning solar panels is a job for professionals - do it, but do it the right way!”