The spectacular "Bridgestone World Solar Challenge 2017" led 3,000 kilometers from Darwin in the north to Adelaide in the south across Australia. The Japanese Tokyo University team, which was supported by the Panasonic Corporation with solar modules and lithium-ion batteries for its racing car this year, came fourth place. In the 30th anniversary of the race, 45 teams from 29 countries participated. "The Bridgestone World Solar Challenge is one of the toughest solar vehicle races in the world and demonstrates the tremendous performance of solar technology," said Shigeki Komatsu, General Manager Solar Europe at Panasonic. "We congratulate the team on the successful participation."

Downsized solar module installation area of four square meters

From 2011, Panasonic has supported the Tokai University Solar Car Team by supplying them with advanced components, such as HIT solar modules boasting top-class power generation, and high-capacity lithium-ion batteries.

Compared with the most recent race, the main change in this year's car is a downsizing of the solar module installation area, from 6 square meters to four square meters. This has enabled a dramatic change to a monohull design, resulting in a reduction in wind resistance, and a stunning new appearance.

24.1 percent efficiency – output of 962 watts

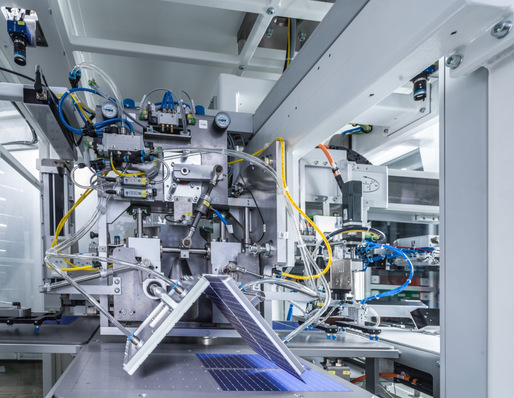

In order to secure maximum output from the smaller module area, Panasonic provided the team with R&D level technology for the first time. By using a technology called back-contact, which mounts all of the electrodes on the rear side of the solar cells, the power-generating efficiency of the cells reached 24.1% for an output of 962 watts (increasing the power-generating efficiency of the cells by 0.9% over the 2015 model).

The HIT solar module that Panasonic has supplied since 2011 uses unique heterojunction solar cells that combine a crystalline silicon substrate with amorphous silicon thin film. Compared to ordinary crystalline silicon modules, there is a smaller drop in output power at high temperatures. This positions the HIT solar module in the top class of power generation per unit area. HIT solar modules are also well suited to the race in Australia where the modules reach high temperatures due to the strong Australian sunlight.

Lithium-ion batteries with nickel-type cathode material

Panasonic's lithium-ion batteries use a unique nickel-type cathode material to achieve the industry's highest level of energy density in a cylindrical 18650 size (diameter: 18 mm, height: 65 mm). This allows more of the power generated by the HIT solar module to be used to recharge the lithium-ion batteries, and enables the car to travel longer distances on overcast days with less sunlight.

By combining the HIT solar module, which boasts the world's highest level of conversion efficiency for mass-produced solar cells, with high-capacity lithium-ion batteries, Panasonic offers an energy solution that links energy creation with energy storage to support the Tokai University Solar Car Team in challenging the Solar Car Race under such grueling environmental conditions. (HCN)

Read more about energy storage

Stay informed, get our free newsletter twice a week. Register here.

More useful information:

http://www.pveurope.eu/News/Energy-Storage/From-a-supermarket-to-a-smart-home-with-energy-storage

https://www.pveurope.eu/solar-modules/panasonics-solar-panels-designed-residential-applications