This year, the Intersolar in Munich was truly a bonfire of the innovations. Anyone who was thinking that solar panels and inverters were at the peak of their technological capabilities was in for a surprise. A pleasant one: The suppliers of string inverters and battery charging technology had quite a lot to offer. One thing is clear: The power density of the inverters is going up, i.e. the units are becoming more and more compact. With the smaller units, the battery inverter is already integrated into the string unit. And the costs for larger units oriented towards the project segment of the market continue to come down. Again, they are becoming more compact and easier to install.

Hot core inside the inverter

When it comes to real innovations, SMA had kept a low profile for some years. Now the engineers from Niestetal are acing with a completely novel inverter concept. The Core 1 is a commercial string inverter with an output of 50 kilowatts. It applies the new concept of the hot core. Not a nuclear reactor, but rather a specific positioning of the cooling elements at the heart of the unit.

This idea was rewarded with this year's Intersolar Award, because it is a real milestone on the road to lighter and higher-performance inverters. The hot core was developed by SMA, the Fraunhofer Institute for Solar Energy Systems, Pheonix Contact and the Fraunhofer Institute for Manufacturing Technology in Dresden. “Our aim was to make the components even more compact,” Stephan Liese of the Fraunhofer Institute in Freiburg explains. He is the head of the working group power electronics there. In Munich the ISE presented a Core inverter with 70 kilowatts. A surprisingly compact unit.

Learning curve analogous to computers

The founder of SMA, Günther Cramer, had already foretold years ago that inverters would be subject to a similar learning curve as PCs and laptops: smaller and smaller components, rising energy and performance density, more functionalities. The integration of storage batteries so far is not relevant to the project sector. But what has become commonplace for smaller inverters directed at end customers, should soon also be state of the art in commercial-scale units.

SMA’s Core 1 uses the centrally located cooling element on two sides: One side radiates the heat from the DC circuit, the other from the components converting the output into AC. In the floor of the unit there are small fans that draw in air, which then rises within the inverter as in a chimney and thus contributes to the cooling effect.

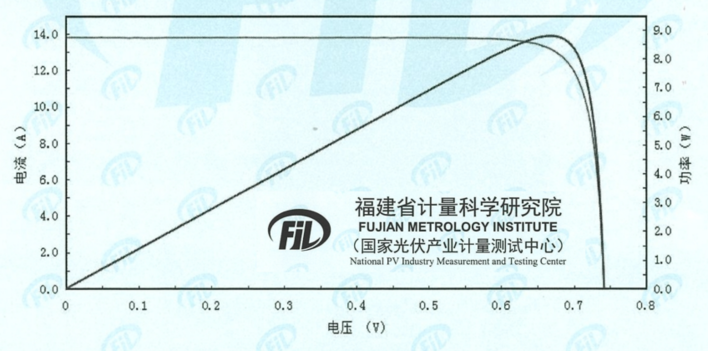

The power components contain parts made from silicon carbide. They tolerate higher temperatures and have greater stability compared to classic power transistors made from silicon.

Fronius is 37 percent ahead

SMA had their work cut out to keep their competitors Sungrow and Huawei at bay. In the commercial segment, the Core puts SMA in quite a good position. As far as smaller inverters for private customers are concerned, SMA has lost considerable market shares in Germany as well. Here it is the smaller manufacturers such as Fronius or Kostal that are setting the standards. “We are having an amazing year which is posing a few challenges for us,” Martin Hackl, head of Fronius’ solar division, comments. “Our planning has been far exceeded. As of late April, we have had 37 percent more orders than during the same period of last year. We are having a lot of fun at the moment.”

Some years ago, Fronius had already begun to optimise their snapINverter for self-consumption. The battery is controlled by the same inverter that also manages the solar strings. Beyond that, there are relay connectors where, for example, high power consumers can be added as needed. Emergency power is also possible: “Emergency power supply is a topic that adds a spark to every sales pitch,” Martin Hackl confirms.

Many ideas for integrated energy

In Munich, Fronius presented a number of new ideas for integrating heat and electro mobility, i.e. integrated energy: “Our Ohmpilot will start shipping this summer,” Martin Hackl promises. “We have already received a lot of orders for this unit. It is simple to connect to the inverter and can control any electric heat source up to nine kilowatts.” Via a heating cartridge, the Ohmpilot diverts any surplus solar power into producing hot water, thus creating a connection between electricity and heating. The heating element’s output is modulated according to the amount of electricity supplied by the roof.

Also, Fronius are cooperating with Okofen, an Austrian manufacturer of wood pellet boilers. This year, Okofen came out with a neat cogeneration plant that has a Stirling engine above the combustion chamber. It generates 600 watts of electricity and augments the power supply during the winter. “This will allow a great degree of self-sufficiency,” Hackl predicts. The cogeneration plant is connected to the Fronius inverter and uses the connected battery (Fronius Energy Package) as a buffer. This AC-linked system can also supply emergency power.

EVs as part of the self-consumption

Along with Delta, Fronius was one of two manufacturers of inverters that are already thinking in terms of electric mobility. Together with Loxone, Fronius developed a system for integrating EVs into the self-consumption. “The Loxone system passes the solar power on to the wall box,” Martin Hackl explains. “The car acts as a mobile storage battery. Of course, it is also possible to connect the wall box directly to the inverter via the relay connectors, as a threshold switch for solar power. But the Loxone system is more efficient.”

Delta is also paying attention to the issue of electric mobility. This manufacturer of solar inverters has developed a high-performance charge point with an output of 150 kilowatts. This is used by ClickCon for their solar carport. This charging point is compatible with almost all typical plugs and makes of car.

As to inverters for private end customers, Delta presented their new H3 series. They have completely redesigned their small single-phase inverters. But size is not everything: The three-kilowatt H3 switches over to AC yield when the output from the DC string is as low as 30 watts. “In other words, this unit connects to the grid very soon and does not switch off until very late in the evening,” Andreas Schmidt, head of sales, says. “We integrated Wi-Fi connectivity, so the unit can be controlled by a mobile device.” It does no longer have its own display. Delta conducts their distribution through retailers, e.g. Baywa or Krannich.

Kostal presents new Plenticore Plus

Kostal from Hagen also demonstrated in Munich that they have been eager to innovate. The new battery inverter Plenticore does exactly what the name suggests: On the one hand it is plentiful in its variety. The Core element of the name has nothing to do with SMA’s Core concept, but in this case stands for the core functions that are all united within one unit – the heart of any system for self-consumption. This inverter has two inputs for solar strings and one further DC input for connecting either another solar string or a storage battery. The battery can also be integrated at a later stage.

The batteries are connected as high-voltage systems, like the ones of BYD, Kreisel or LG Chem (Resu HV). When replacing old inverters (repowering), the new unit achieves higher yields and more self-consumption, and integration into a smart home is also possible and simple. Also, it allows the management of further AC generators without the need for additional components or interfaces. The Plenticore Plus has a separate terminal compartment with all the interfaces and is equipped with tool-free Sunclix connectors. It is meant be available no later than the first half of 2018.

ABB are extending their product range

ABB, what used to be Power One, took their new 100-kilowatt and 120-kilowatt string inverters to Munich. These units will be available in late 2017, and the system voltage will soon be raised to 1,500 volts (DC). This inverter is designed for large-scale commercial and industrial installations as well as for ground-based projects. It is very low-maintenance and thus reduces overheads. Because it allows IP-based communication, has a cloud architecture and can be launched wirelessly, it can be configured via a tablet computer or any other mobile device.

ABB have also added to their three-phase string inverters: The Trio TM’s version with three MPP trackers has an output of 60 kilowatts. The Embedded User Interface makes launching it through any Wi-Fi-capable device quick and easy. Furthermore, the A Sunspec-compliant Modbus protocol also enables easy integration with third-party monitoring and control systems.

Last but not least, ABB presented their Uno DM Plus single-phase inverter. This compact unit is available in versions ranging from 1.2 kilowatts to five kilowatts. They can also be controlled via smart home systems. Plug-in connectors allow an easy, fast and cost-effective installation without opening the outer casing. The integrated user interface gives access to functions such as advanced settings for the inverter, dynamic feed-in control and load management.

AEG is back in business

Solar Solutions, sales partner for solar products of AEG, supplementing their range of solar generators by single- and three-phase string inverters ranging from 750 watts to 50 kilowatts. The units are compact, lightweight and user-friendly when it comes to installation and starting up. They have a built-in operating system for trouble-free installation and an integrated monitoring functionality to keep overheads low. AEG’s new inverters will be available starting this summer. (Heiko Schwarzburger)

Learn more about solar modules

Learn more about energy storage

Learn more about electric cars

Learn more about power electronics

See Fronius´vision 24 hours of sun

Stay informed, get our free newsletter twice a week. Register here: https://www.pveurope.eu/newsletter