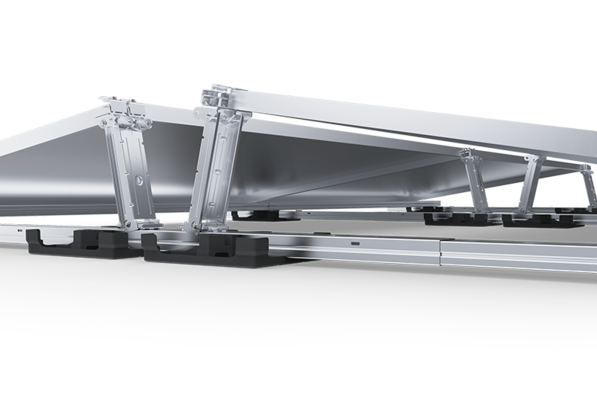

The MSP mounting systems are provided by Swiss supplier Ernst Schweizer AG. If additional ballast is required, paving stones are first placed in the supports and then the struts for placing the stones are doubled. If necessary, the base plates must then be enlarged and adapted to the specific conditions.

The space on the roof can be used optimally, because is possible to combine east-west and south-facing systems, leave out individual panels and build around skylights without cutting.

Rigorous tests in the wind tunnel

The distance between the rows can be freely selected thanks to the different connecting rails in the southern system, so that a shade-free system can even be installed in northern Europe. Both variants can be freely aligned in any direction. They do not require roof penetration and no surveying, clamping or drilling work on the mounting system.

The systems were rigorously tested in a wind tunnel according to the guidelines of the Wind Technological Society (WTG) and designed for the location-specific peak wind speeds. These can exceed 200 kilometres per hour. Ernst Schweizer AG grants a warranty of ten years. Since the connections do not require crimping, non-destructive conversion or dismantling is possible without any problems.

Sophisticated design software

The manufacturer has aimed to reduce ballasting to a minimum in order not to exceed the load reserves of roofs while still ensuring safety. The success is based on the thorough wind tunnel tests and the resulting structural calculations with the associated load combinations and safety margins. For the design, Ernst Schweizer AG maintains the software proMSP (formerly Profis), with which the necessary ballast can be reliably calculated and documented.

In addition to the system parameters, building and attic height, terrain category and snow and wind loads, proMSP also takes into account the long-term compressive strength of the insulation material and the protection against slippage on the roof foil.

Since there is no uniform information from industry associations on the extent to which snow, wind and the specific weight of the solar panels can be applied to the respective insulation material, the Ernst Schweizer AG also goes directly to the manufacturers of insulation boards – such as Knauf, Isover-St. Gobain, Flumroc and Rockwool – for the appropriate certificates on loading the base profiles.

The matching profile for every insulation material

In order to prevent deformation in the insulation materials and damage to the roof cladding, Ernst Schweizer selects its basic profiles according to the maximum load-bearing capacity of the insulation material. Thanks to its variable supporting surfaces, the company's mounting systems are suitable for 95 percent of all insulation materials.

For example, large base plates are used for high bearing pressure due to heavy snow loads on a very soft insulation material. In this case, the load is distributed over a larger area, which prevents the base plates from sinking deeper into the insulation material and limits the wear and tear on the roofing film to an acceptable level, as is the case for a 215 kilowatts system in Augsburg with soft mineral wool.

An example without additional ballast

In another installation, base plates with a contact surface of 43 by 25 centimetres and 88 by 25 centimetres were used as insulation material in order not to exceed the maximum permanent compressive strength of up to two percent compression.

The solar system was installed on a building with a height of ten metres in terrain category III (city centre) and wind zone 2 (wind speed 25 metres per second). According to DIN EN 1991-1-4, this results in a gust velocity pressure of 0.624 kilonewtons per square metre.

At a terrain height of 480 metres above sea level and snow load zone 1a, the typical snow load on the ground is 0.81 kilonewtons per metre according to DIN EN 1991-1-3. This project, with its large contiguous blocks, did not require additional ballast.

265 kilowatts in western Switzerland

In yet another example, Ernst Schweizer AG used smaller base plates with additional paving stones in the supports for a 265 kilowatts project in western Switzerland. The bitumen roof was insulated with rigid PUR foam. At the rural location, there is little snowfall, but the local wind forces are very high with a dynamic pressure of 0.9 kilonewtons per square metre.

The ballasting plan shows that 13.5 by 28 centimetres base plates were used. In order to secure the system against shifting and lift-off under the given wind conditions, it was necessary to additionally weigh them down in various places using paving stones.

Safety calculation

When installing the solar systems on roofs with a maximum inclination of three degrees, Ernst Schweizer see no need for further tests or on-site connections. From three degrees upwards, the company recommends mechanically securing the mounting system. This avoids the so-called caterpillar effect, which can occur when the membrane and the mounting system, which is made of metal after all, show varying degrees of thermal expansion of.

The solar panels are adequately secured against lift-off and shifting, even during century storms, as the August 2017 hurricane over Passau showed. If the properties of the roofing membrane are not known, Ernst Schweizer either factors in additional load as security measure or determines the friction coefficient.

Free software available

On the basis of all this data, the free software available from their website creates a complete documentation of the structural calculation. In addition, it generates the parts lists and drawings for fast and safe installation. With 3D visualisation, the layout of the array can be planned quickly and easily, and the roof can be covered according to specifications. Via web tools or during customer appointments, Ernst Schweizer instructs installing companies or technicians on how the software works. In most cases, the company also designs the solar systems free of charge for its customers and carries out customer-specific initial installation instructions at building sites. (Dr Helge Hartwig)

Dr Helge Hartwig is Head of Sales and Technology for PV mounting systems at Ernst Schweizer AG.

Read this, too:

http://www.pveurope.eu/News/Installation/Flat-roof-mounting-Mathematics-outweighing-ballast

http://www.pveurope.eu/News/Installation/Bespoke-solutions-for-tricky-flat-roofs

http://www.pveurope.eu/News/Installation/Module-installation-Stable-systems-for-all-roofs

http://www.pveurope.eu/News/Installation/Sjef-de-Bruijn-from-Ernst-Schweizer-AG-We-have-to-be-very-efficient

Stay informed, get our newsletter twice a week.

Register here: http://www.pveurope.eu/Newsletter

Read more on PV in Europe:

http://www.pveurope.eu/News/Installation/Advanced-mounting-solutions-for-British-and-Irish-roofs

http://www.pveurope.eu/News/Solar-Generator/PV-Guided-Tours-More-roofs-fewer-parts

http://www.pveurope.eu/News/Installation/Solrif-in-roof-systems-for-housing-projects-in-England

Read more about solar modules.

Read more about solar energy storage.