The high cost of battery cells continues to be a major stumbling block to improving the cost-efficiency and popularity of e-mobility and energy storage systems. Roughly a third of battery production costs are currently accounted for by the final step in the manufacturing process: the application of the initial charge, known as formation, which is key to the performance, durability and safety of battery cells.

Study the formation process in detail

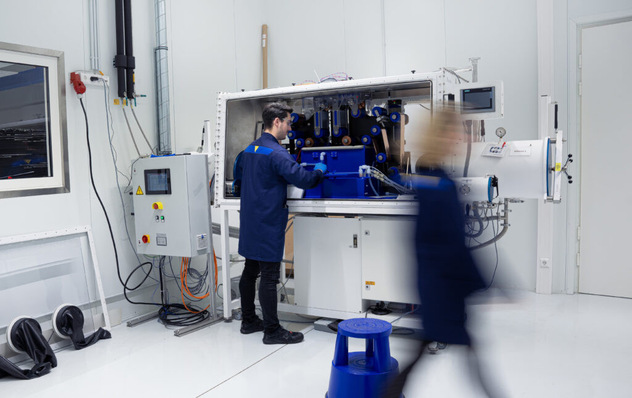

Under the collaborative project “EffiForm - Efficient formation strategies for increased durability, reliability and safety as well as cost reduction in the production of lithium-ion cells/batteries” Thyssenkrupp System Engineering is partnering with VARTA Microbattery GmbH, BMW Group, Scienlab electronic systems GmbH, Fraunhofer IKTS, the Technical University of Munich and the MEET battery research center of Westfälische Wilhelms-Universität Münster to study the formation process in detail.

Optimize the material, process and systems technologies

The aim is to optimize the material, process and systems technologies used in the initial charging (formation) of lithium-ion cells for industrial applications. The “EffiForm” project is being funded by the German Federal Ministry of Education and Research (BMBF) as part of its program “Battery 2020 – battery materials for future electro-mobile and stationary applications”.

Creating the basis for efficient industrial-scale formation

Over the three-year project period, Thyssenkrupp as a supplier of formation systems will focus on creating the basis for efficient and innovative industrial-scale formation. “This will be a key step in translating the project findings into cutting-edge formation systems for the mass production of lithium-ion cells”, company spokesman Torben Beckmann said. In the future this will reduce the production costs of li-ion battery systems and support the spread of e-mobility. Lower costs could also make li-ion technology more attractive for other energy storage applications, the company hopes. (HCN)

Read more about energy storage

Stay informed, get our free newsletter twice a week, register here

Related news: