Everybody is taking about electric cars. But somehow business is very slow to get going. How are things going for you?

Franz-Josef Feilmeier: We are developing and producing storage systems for commercial companies and utilities. And we are introducing EVs to our B2B partners. Both of these things do not develop very quickly or overnight. They involve complicated projects that require time. But we knew that six years ago when we started Fenecon.

Your main partner for supplying the batteries and cars is BYD. What products are we specifically talking about?

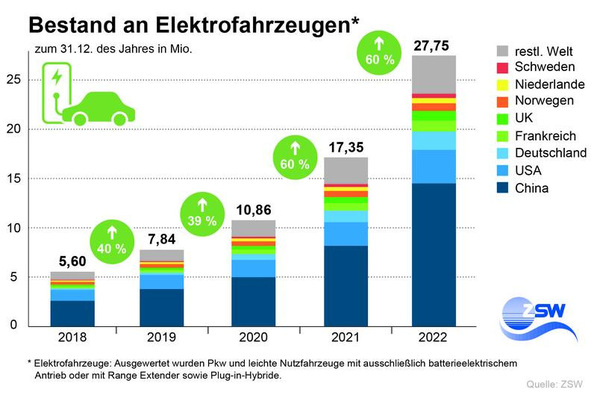

BYD is one of the largest manufacturer of lithium iron phosphate batteries: Anything between a small solar battery and an integrated large-scale storage system. What people here tend not to know is that BYD also manufacture solar panels and EVs. Those are both private vehicles and also electric busses. In China, BYD is having a great deal of success with that. Last year China has seen more than half a million new electric cars on the roads.

What vehicles are imported to Europe?

We are being supplied first of all with BYD’s e6, primarily as taxis, which has 400 kilometres of realistic range. They are imported through BYD in Rotterdam. One of their taxis is being operated as a test in Regensburg, more will be used in Munich soon. For now we intend not to sell the e6 to private customers. When it comes to taxis, servicing is handled differently. Taxi firms can take care of that themselves.

Speaking of Munich, is it to be expected that at next year’s Intersolar, we might be taken to the venue in a fully electric e6?

For now we are talking about ten taxis. Munich city council has put together a lucrative funding package to make the transition to fully electric vehicles easier. We already had an e6 as part of a trial phase and looked at by an automotive technician. In terms of technology the vehicle could absolutely hold its own, especially by the high standards of taxi operators.

Such as?

A taxi does about 100,000 kilometres per year and runs for four to five years. In addition to the fuel costs, the most important factors are the cost of maintenance and the service life of the battery. Also, vehicles used as taxis need a specific certification. It took us nine months to get our e6 taxi-compliant for Germany. However, dieselgate was very good for us: Slowly people are changing their minds.

How are the e-taxis being recharged?

That is an important part of the project. The vehicles can be rapid-charged at any conventional type-2 40 kilowatt charge point. This way there is no need for expensive DC-based infrastructure while still allowing to quickly recharge the vehicles. In projects with a number of vehicles or busses, it can be advisable to use a stationary battery system to buffer peak loads and avoid having to extend the grid. Such a peak shaving battery would mostly come into play if there are many taxis that need to be charged. If possible, a PV array can also be connected to the storage unit, as it might also interesting to B2B fleets to charge up their vehicles with solar power.

So stationary and mobile batteries work hand in hand?

Correct. But it adds to the expense and the complexity of such projects. However, since we are in collaboration with BYD, we are able to offer all products from the same source, including the solar panels. The storage business is going very well. BYD is currently building their second 50 megawatt large-scale storage system in the UK. Our key storage markets are currently in Germany, Austria and Switzerland.

Are you also offering other vehicles, such as buses?

Electric busses are indeed a very economical and ecological manifestation of electric mobility. BYD is so far successfully operating 10,000 e-busses worldwide. Soon we will also have the first fleet of them in Germany. At the end of this year we will furthermore present the T3, an electric van specifically targeted at tradespeople and delivery services.

Street Scooter is already pretty successful in this field...

Yes, but their vehicles are fundamentally different. With the used Street Scooter batteries we have projects as they are common in the e-mobility circles: The power required to charge a number of vehicles simultaneously would usually necessitate an upgrade of the grid which in inner cities or rented properties can often be a lengthy and expensive process. Stationary batteries can help to solve that issue and nowadays are often less expensive than a standard upgrade. And such battery systems can take over other functions. Using our expertise in system integration, we are able to use second life batteries to realise an entire commercial-scale storage system including intelligent energy management. Among electric car makers there currently is a lot of demand for that sort of thing.

Is there increasing demand for such commercial storage units?

People are beginning to pay more attention to the issue. But so far, very few actual projects are are being built. A storage system for commercial or industrial applications is much harder to sell and install than a compact unit aimed at private customers. The uses that it can be put to are different. Fenecon are positioning themselves as a competent system integrator, rather than chiefly as an EPC. Analogous to the PV sector, project planners for large-scale storage projects are currently establishing themselves. In addition to the technology itself, funding, insurance or underpinning the advantageous effects of the peak shaving.

So the value chain is restructuring with an eye to the growing markets?

That is correct. Project developers are currently most keen to demonstrate that they know what the sector is about. They need references in order to position themselves. This has all happened very swiftly. Two years ago the only enquiries for larger storage systems were related to self-consumption of solar power. Today we are dealing with a wide variety of applications, such as peak shaving which I already mentioned, reinforcing power grids – and of course self-consumption as well. Furthermore, there is uninterruptible power supply and high-output applications.

Where have Fenecon energy storage units been installed?

We sell our products through installing companies/EPCs, wholesalers and increasingly via utilities. By now our units can be found in 16 countries on 3 continents. In Germany, we are most prevalent in Baden-Württemberg, Bavaria, Saxony and North Rhine Westphalia. A good number of funding applications are open there, but the authorities are quite slow to process these. In Austria and Switzerland we have installed mostly three-phase systems. Emergency power is a big issue there. In Switzerland, where we are in cooperation with the BayWa subsidiary Solarmarkt, the Fenecon Pro 9-12 is going strong.

What about other European countries?

We have so far been doing less in terms of actively marketing there, but together with strong local partners we are now building up the markets in Italy, the Netherlands and Czechia. We currently have a staff of 45 and cannot spread ourselves too thin. Next year we will continue to grow at a moderate rate. For us it is not about serving as many overseas markets as possible. But on the other hand we are already in the black and have a sustainable business model – which is rare in this sector.

The smaller energy storage batteries are supplied as complete units through sales partners?

For the integrated storage systems, we are the exclusive partner of BYD and market these as Fenecon systems, including our FEMS energy management system. With our product lines Mini, Pro, Commercial and Industrial we cover the entire spectrum. We were involved in the development of the B-Box series which is purely a battery product – and which is available in low- and high-voltage versions for combining with external inverters. This is marketed through the partners of SMA and Kostal as just one of many batteries as well as through us in our role as BYD’s partner. In addition to our partners, we thus also supply other wholesalers and provide our batteries for specific projects.

What projects are you building in Austria?

In Vienna, we have built special grid balancing units. Five larger-scale batteries filter the asymmetries out of the grid power. Simultaneously, they operate in reactive power control and peak shaving. Through an FEMS connection to the power station’s control room, they can also be put to other uses. We have realised these projects in cooperation with our partner REFU. E.ON in Hungary has now ordered a similar system. We know what challenges grip operators face, and so we have designed our Pro series in such a way that it can also operate asymmetrically in on-grid mode. This opens up a completely new market with ample opportunities for generating more income or connection more PV capacity.

What exactly do you have in mind?

By increasing the quality of the grid output in terms of reactive power, phase symmetry etc., the existing power lines can be used more efficiently and enhancing the grid can be avoided. Grid operators are very keen on this, but commercial and industrial companies are also increasingly interested, because it often is the more cost-effective option compared to a conventional upgrade of the grid. And it also keeps energy costs low.

And what does the future hold for electric mobility?

Early next year, BYD will introduce their fully electric van, the T3, in Europe, which can also act as a generator, for instance at a building site. This is what we call ‘vehicle to load’ (V2L). It will have a 48 kilowatt hour-battery and a real-world range of 250 kilometres. This vehicle will open up very interesting and lucrative possibilities especially for builders.

The interview was conducted by Heiko Schwarzburger.

Read more about energy storage

Stay informed, get our free newsletter twice a week. Register here